Check Valves

Check valve is a fundamental component in many water or heating systems. Such components are part of safety fittings, enabling smooth flow of liquids or gases in only one direction. This ensures the entire installation operates efficiently and is not exposed to undesired backflow or hydraulic shocks.

Check valve – structure

Check valves need to be manufactured with utmost precision to ensure the efficient operation of a specific installation. Components of this kind primarily consist of two connections – the inlet and outlet. However, the most crucial part is the flow-blocking mechanism, which serves to halt any attempts of air, water, or other substances from moving in the opposite direction than intended.

Check Valve – principle of operation

Importantly, check valves do not rely on actuators, control levers, or any specialized, modern systems for their operation. The design of such a component is structured in a way that the entire system, along with the proper flow of substances, is controlled by the pressure difference itself. When this pressure reaches a specific level, it triggers the opening or closing of the throttling element. High pressure causes the opening of this part, whereas low pressure leads to its automatic closure. As a result, the level and direction of substance flow are constantly monitored with high precision

Application of check valve

The primary role of a check valve is to prevent backflow within an installation. This allows systems of various kinds to operate continuously according to their expected function and desired efficiency, thereby reducing the risk of malfunctions. The check valve itself offers a cost-effective way to safeguard installations against faults and ensure their performance. Depending on the requirements, various check valves are available, designed to suit pipe sizes, installation types, or their specific placements.

Types of check valves

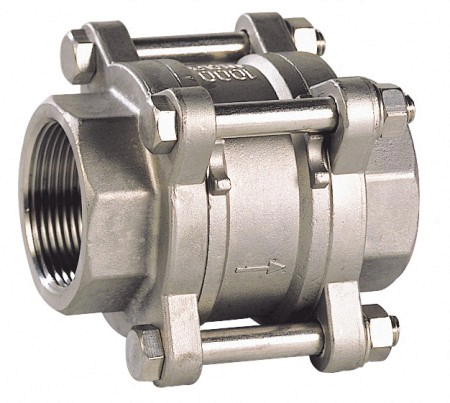

In our store, we offer various types of check valves. One of them is the ball check valve: a product characterized by its distinctive construction, enabling controlled water flow in the proper direction. Its operation depends on the position of a round element – when the ball is lifted, it allows fluid to flow freely, while when blocked, it hinders the operation of the entire installation.

Another noteworthy solution is the vacuum check valve. It is used in pressurized installations, such as those involving water or compressed air. It operates similarly to the ball check valve, although its functioning relies on automatic operation, independent of user actions within the installation. Within our assortment, you can also find the air check valve: typically installed in compressors or compressed air systems. Its role is crucial as it prevents pipe leaks that could potentially lead to system explosions. The air check valve prevents compressed air from retreating back into the tank, operating automatically by constantly monitoring the pressure difference in the throttling element.

Check valves for pipes come in various sizes to accommodate both smaller and larger diameters

The flanged check valve and the globe check valve are components suitable for various external and internal installations. The flanged check valve is designed for use with larger diameter pipes. It ensures a secure and reliable connection that might be challenging to achieve with standard products. Its flanged construction allows for easy installation and removal of the valve. The globe check valve is characterized by having a disc-shaped closure element resembling a globe. It finds application in both heating and water supply installations.

Installation of a check valve

The check valve must be placed in the right location to ensure proper control of the working fluid flow in the installation, typically air or water. To achieve the best results, installation often involves using an air compressor, which facilitates the connection and ensures safe operation for years.