Pneumatic actuators for ball valves and butterfly valves

Valves and butterfly valves are extremely important components in many gas, energy, chemical, and petrochemical installations. Specially adapted drive units are required for their operation. Within the GTM Process Valves offering, you can find high-quality pneumatic actuators for ball valves and butterfly valves, which will effectively automate the installation and ensure maximum efficiency.

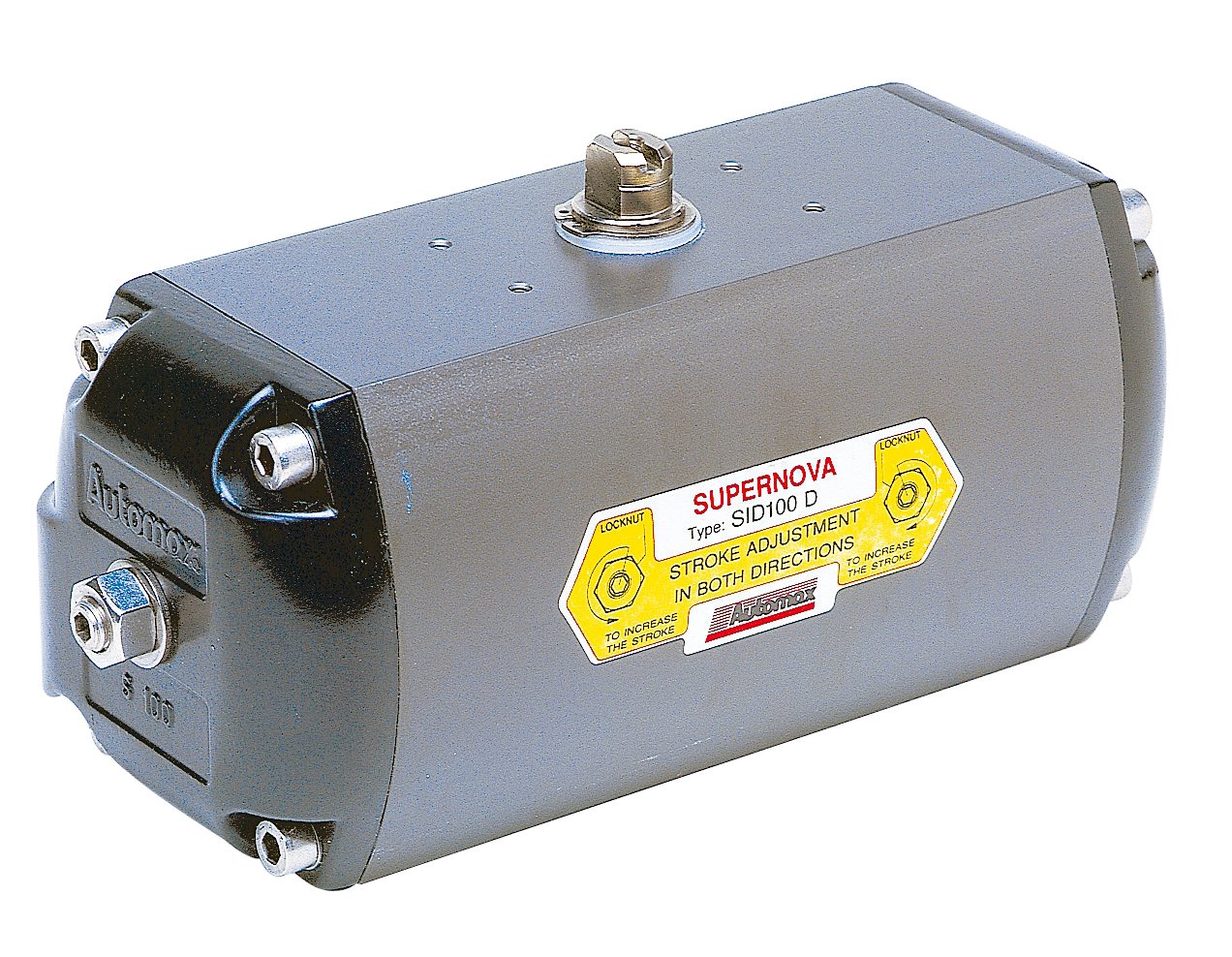

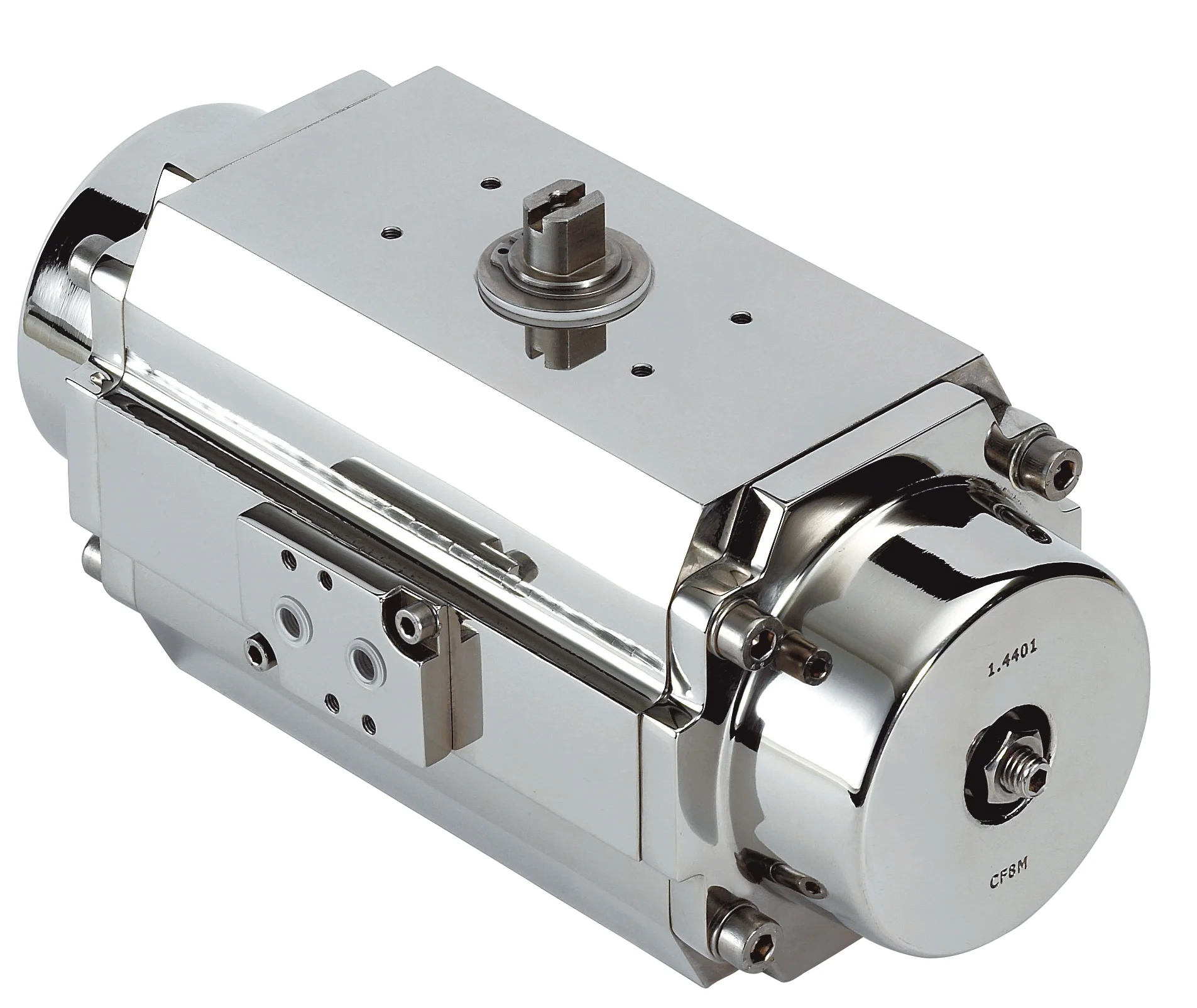

Actuators: Single-acting and double-acting pneumatic actuators

Description: NAMUR VDI/VDE 3845 interface, typically with travel stops (+/- 5°)

Range of torques: 13 Nm – 3235 Nm, higher on request

Connections: ISO 5211 and DIN 3337

Control pressure: 2-10 bar

O-Ring: NBR (standard), Viton (hight temperatures), Silikon (low temperatures)

Body: Anodized aluminum (Standard explosion-proof execution)

Equipment: Limit switches, positioners, control valves

Usage: For controlling butterfly valves and ball valves

Producer: Actreg, Alphair, Air Torque

Pneumatic actuators for valves

Numerous installations in various industries require appropriately matched butterfly valves and ball valves. Without these components, systems cannot function correctly and safely, as they lack the ability to close or regulate flow. To ensure efficient valve regulation, it is worthwhile to invest in the automation of installations, which can be achieved using pneumatic or electric actuators. The task of such a component is remote closing or flow regulation. In the GTM Process Valves offering, you can find a wide range of various types of actuators, allowing you to choose the appropriate drive for a given type of valve or butterfly.

Types and design of pneumatic actuators

Currently, there are many types of pneumatic actuators that differ based on various factors. It is worth mentioning single-acting and double-acting pneumatic drives. The first type is controlled by air in one direction and by a spring in the other direction. Meanwhile, the second type is controlled by air in both directions. Regardless of the specific type, the quality of construction is crucial. In the case of models from our assortment, you can expect high resistance to extreme temperatures and various external factors. O-rings are made from materials such as NBR, Viton, or silicone – the specific choice should depend on the intended use of the actuator.

The body of the drive unit is mainly made of anodized aluminum, which exhibits explosion-proof properties. This is important because pneumatic actuators deal with air under high pressure (from 2 to 10 bar). The current status of the drive unit, as well as any issues, are indicated by a clear and user-friendly LED system. The entire unit can be connected to the installation using ISO 5211 and DIN 3337 connections.

Control for pneumatic actuators

The drive unit alone is not everything when it comes to pneumatic actuation – the proper selection of controls is also important. Two-hand control valves, pilot operated valves, control buttons, and push-button pilot valves are other important components of the system. They enable efficient control of pneumatic actuators while ensuring safety in operation. The appropriate design of valves and other elements helps protect hands from cuts. Such a control system is built with two buttons placed at both ends of the valve, reducing the risk of accidents.

We encourage you to take advantage of the GTM Process Valves offering. Within our assortment, you can find both the actuators themselves and the necessary equipment to prepare proper control for pneumatic actuators. Systems prepared with solutions from GTM Process Valves stand out for their quality, durability, resilience, and resistance to various factors.