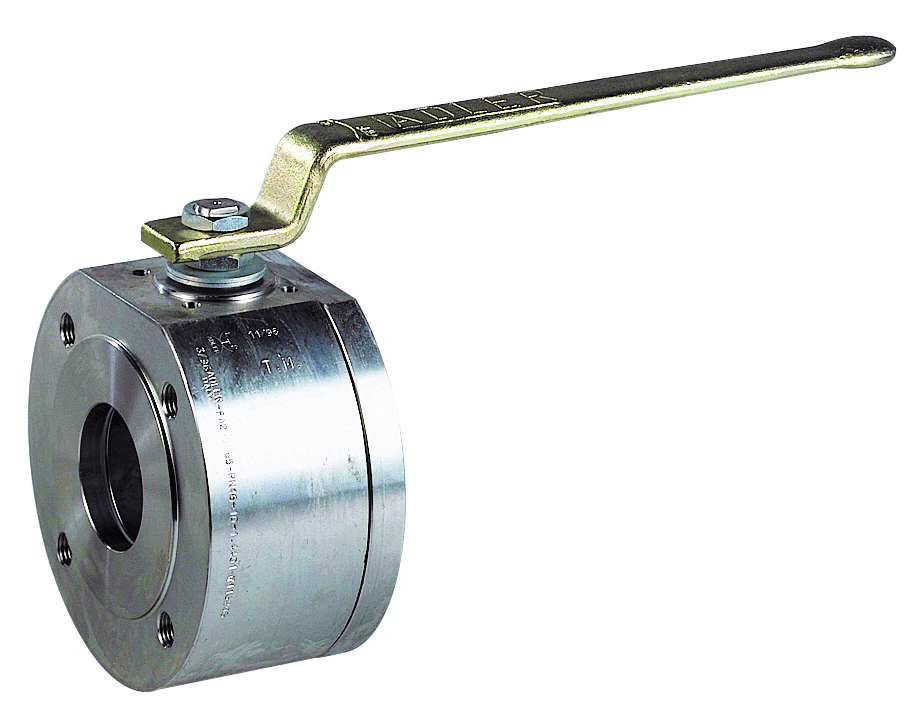

Wafer ball valves

Flanged ball valves are products known for their extremely wide range of applications. They can be installed in nearly all types of systems. Their primary function is to cut off the flow of a medium or to regulate flow in a selected branch of the system. At GTM Process Valves, we offer a wide selection of reliable flanged ball valves, including compact flanged ball valves, ranging from DN15 to DN200, with manual, electric, or pneumatic actuators.

We provide valves from reputable manufacturers such as GTM Process Valves, Andrex, Efawa, Sferaco, JC, and ICP. Our flanged ball valves are top-tier products known for exceptional durability and reliability. They are crafted from materials such as stainless steel, carbon steel, stainless steel, and gray cast iron. We warmly invite you to explore our range of flanged ball valves.

Type: Body: 1-piece; 2-piece

Connection: wafer

Diameters: DN15 – DN200

Pressure: PN16 – PN40

Body: AISI 316 stainless steel, A105 carbon steel, GG-25 gray cast iron

Ball: Stainless steel AISI 314, Stainless steel AISI 304

Seal: PTFE, other on request

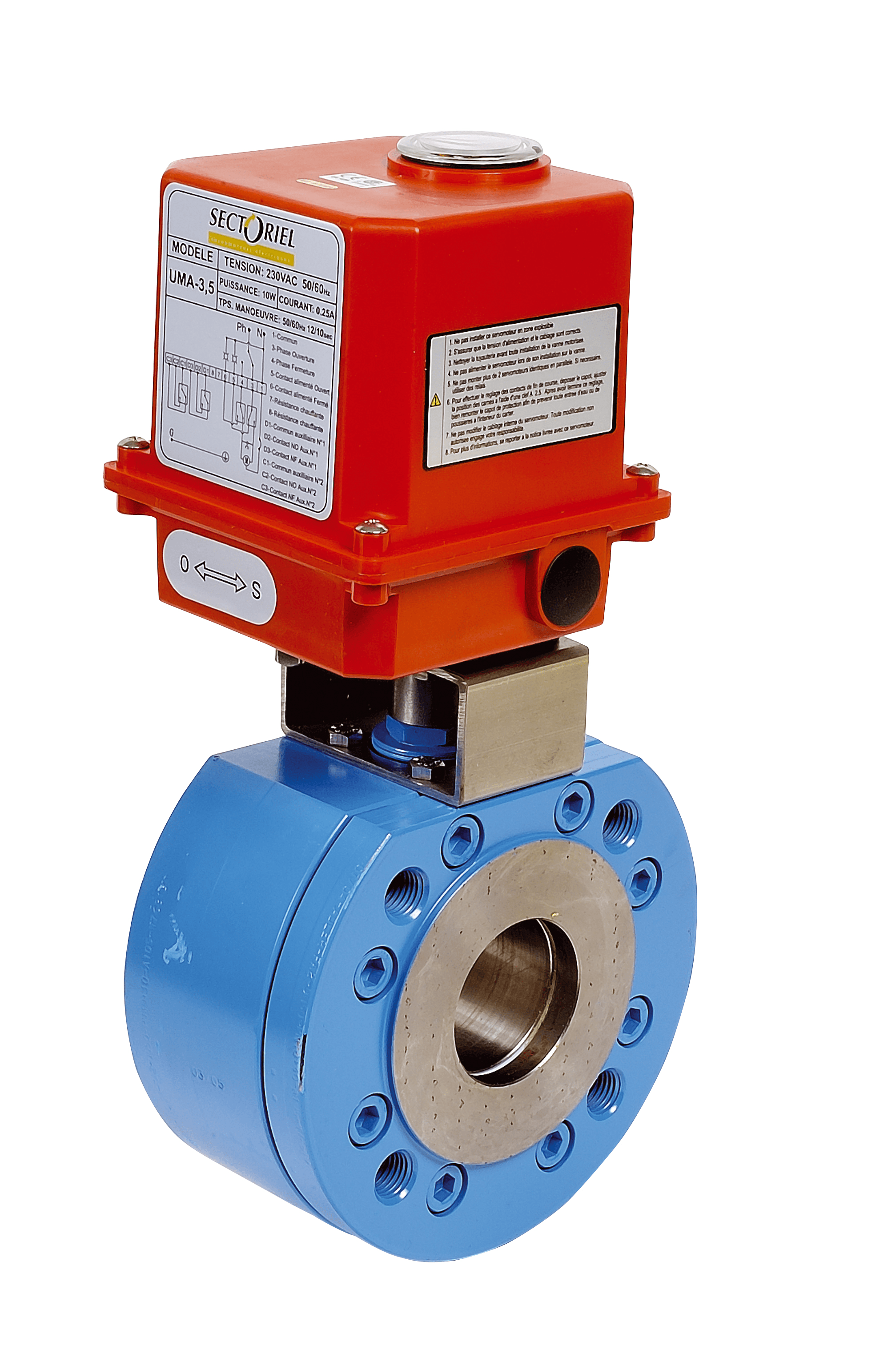

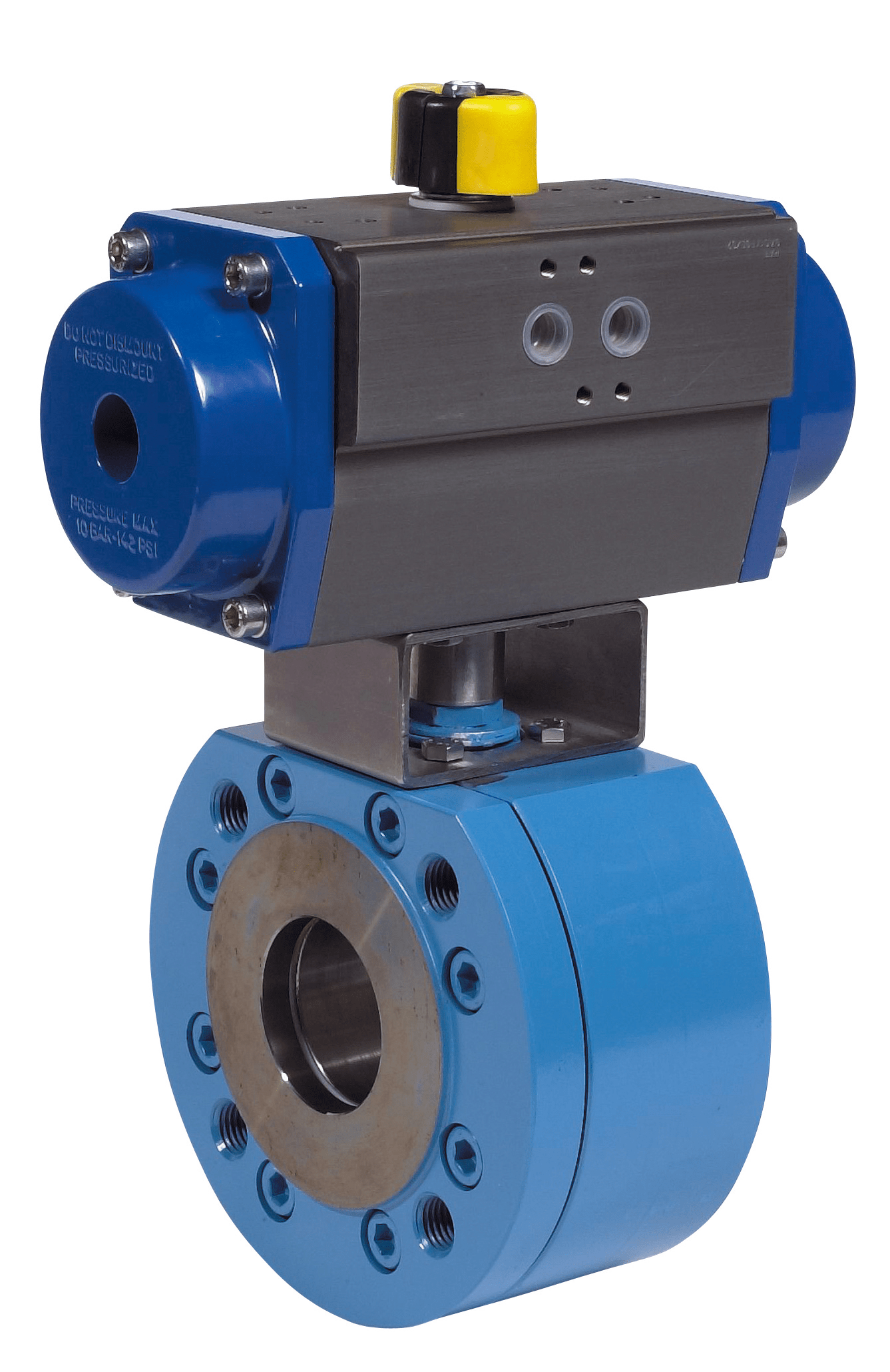

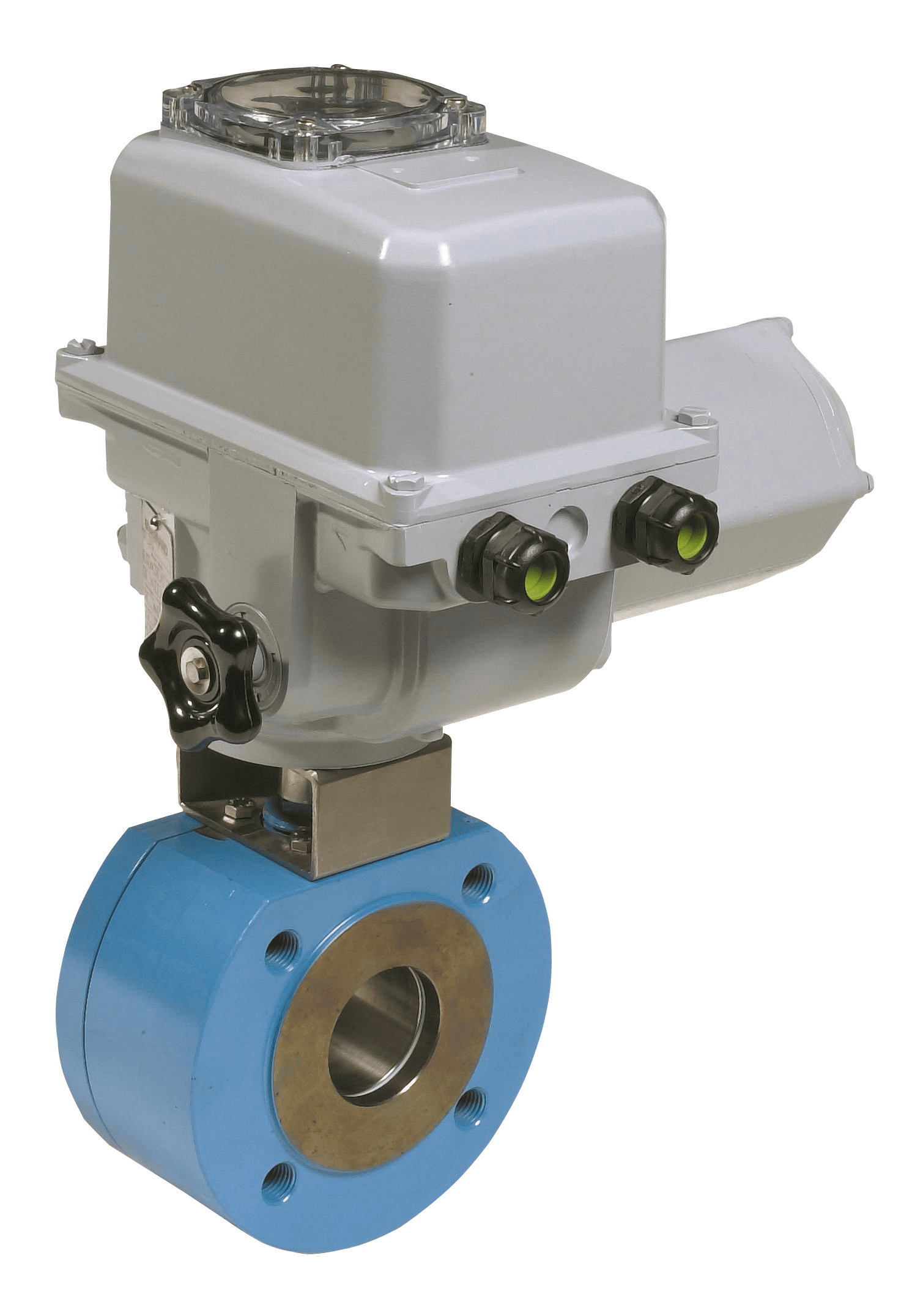

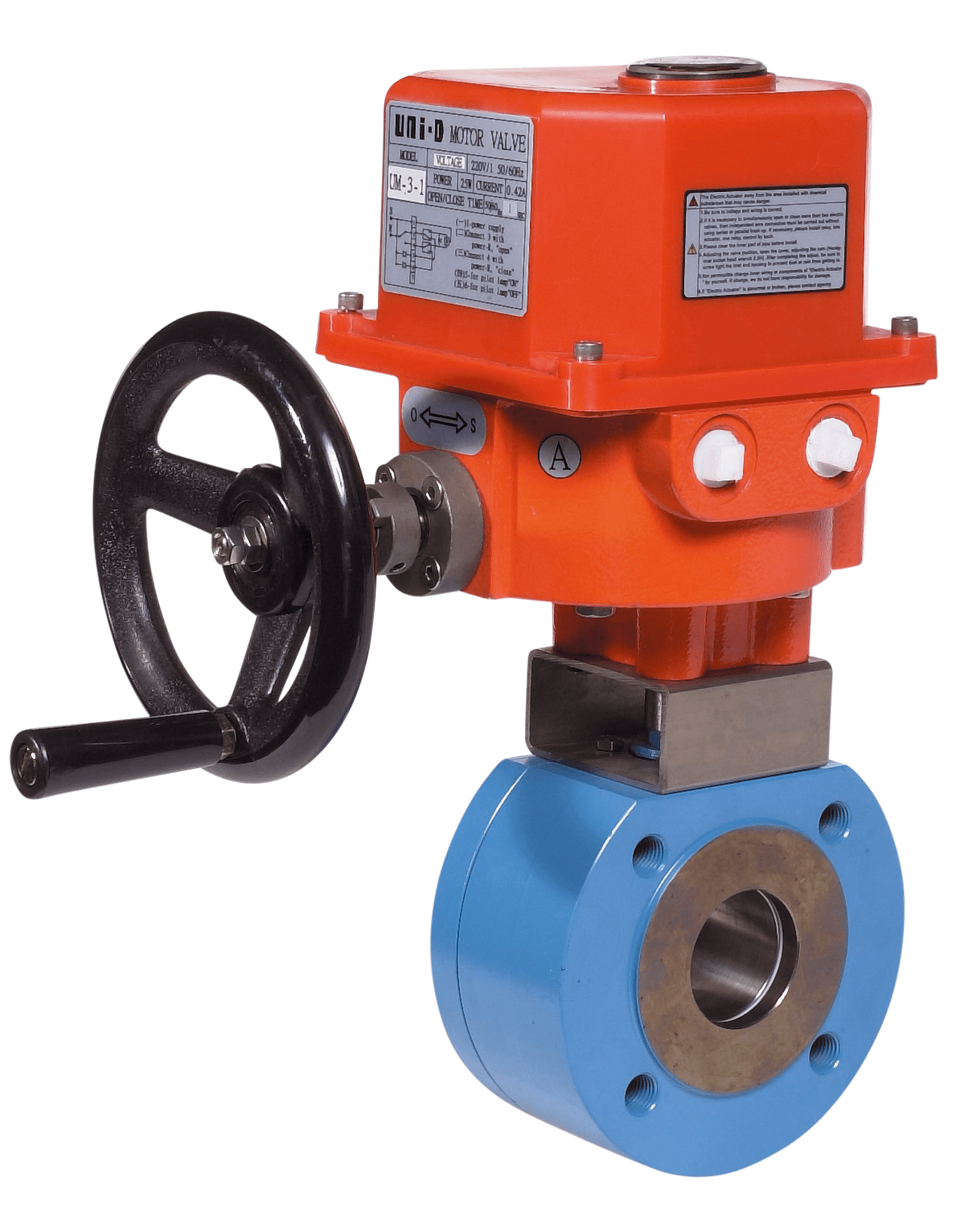

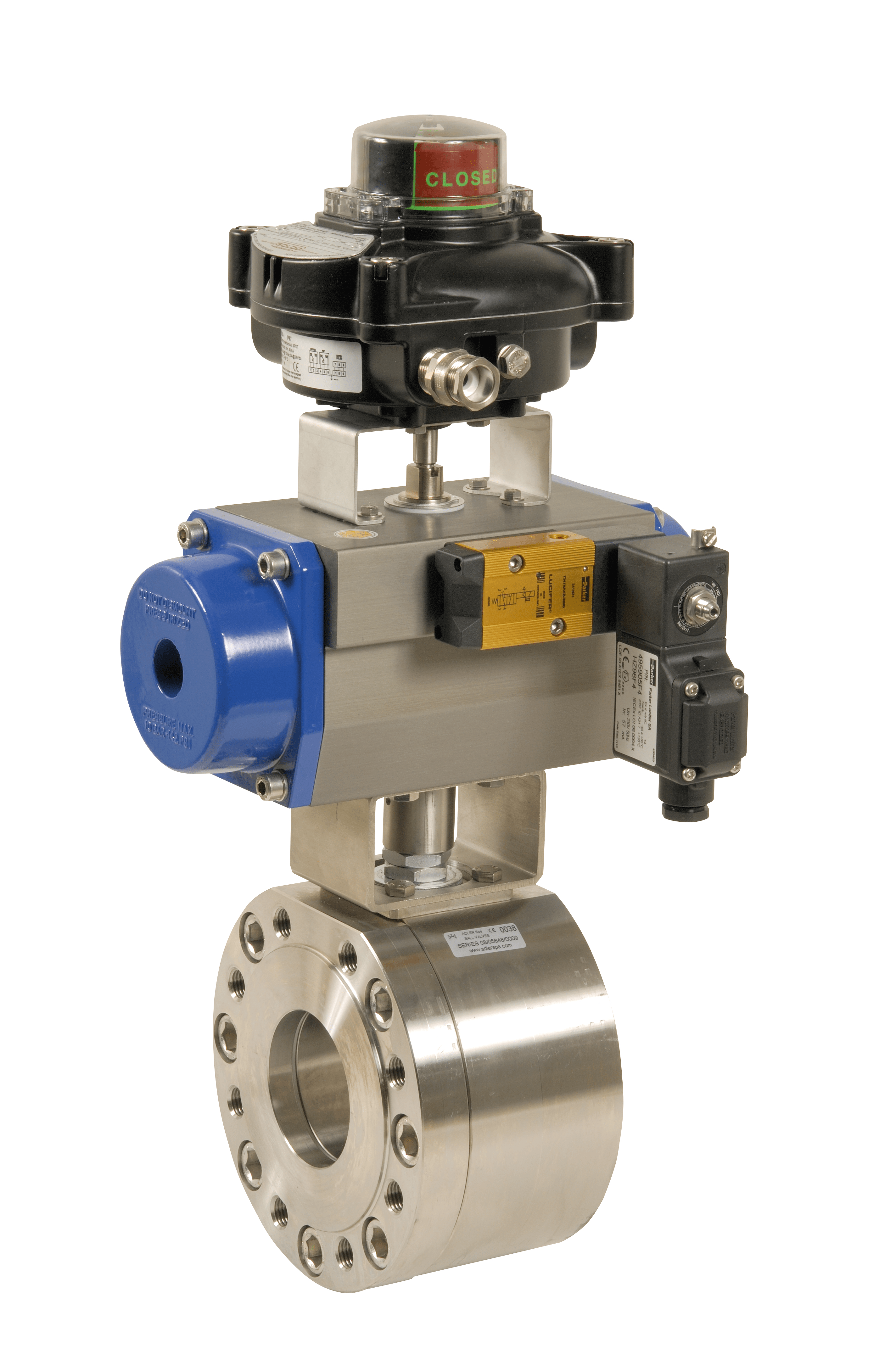

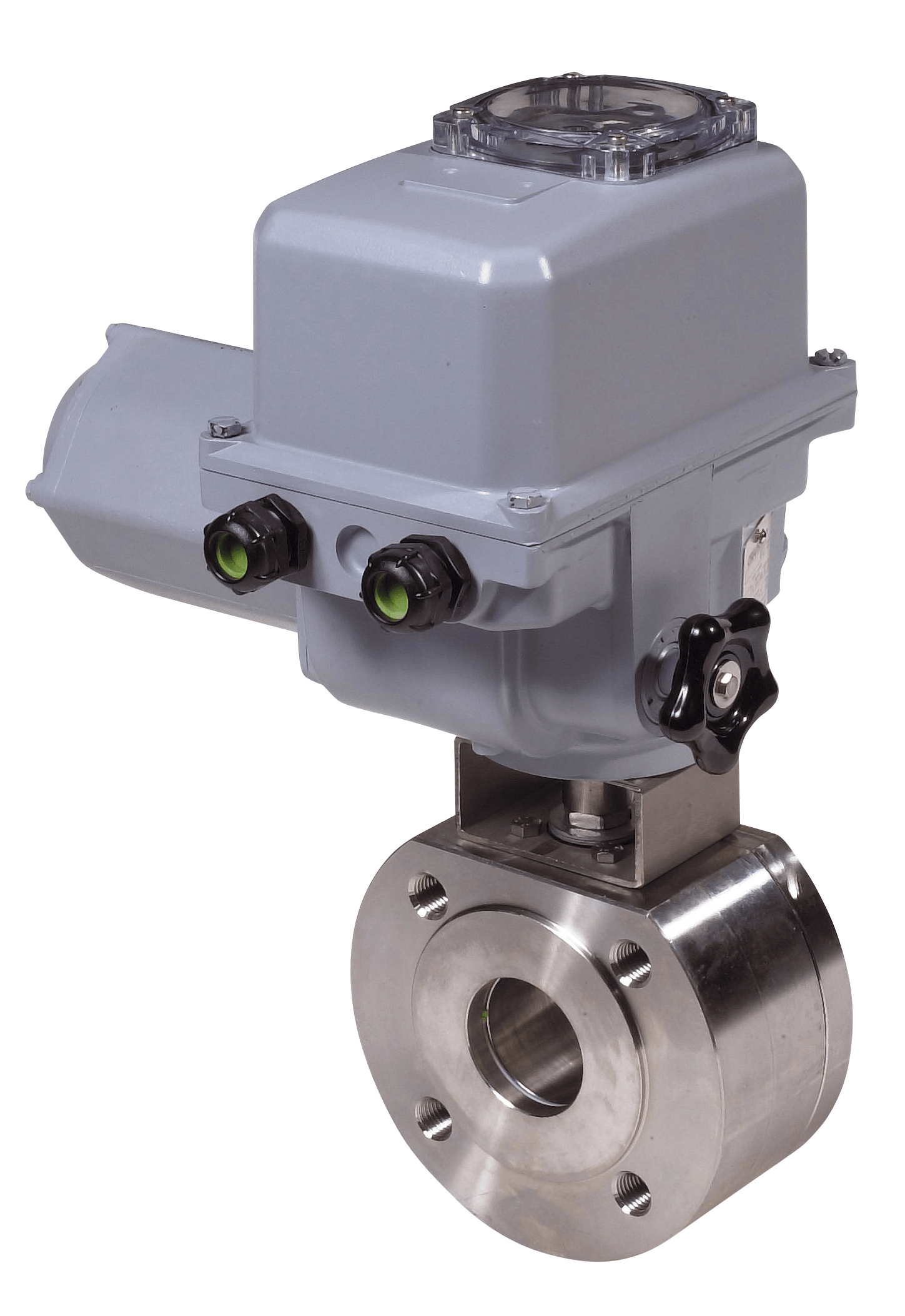

Drive: Manual, pneumatic, electric

Special execution: With heating jacket, without dead spaces, others on request

Usage: Depending on the type, neutral gases and liquids, acids, bases, etc.

Producers: Andrex, Chemitex, Efawa, Sferaco, Cegaz, Adler

What is a wafer ball valve?

Every installer should know what a wafer ball valve is because they frequently encounter this component during their work. A wafer ball valve is one type of industrial valve distinguished by two circular flanges oriented perpendicular to the network’s flow. Between these two flanges sits the ball valve. Typically, all components in wafer ball valves are connected using screws. Occasionally, an additional flat gasket is used to ensure maximum sealing for the component.

Wafer ball valves – characteristics

Wafer ball valves represent a commonly utilized type of valves in the industry and various other sectors. They encompass a wide range of products that vary in size, construction, purpose, and operating principles. Based on their method of controlling flow, flanged ball valves can be categorized into manually operated, electrically operated, and pneumatically operated valves.

Manually operated valves are characterized by their simplest construction. They are most frequently used in various water and gas installations within households. Electrically operated valves represent a slightly more advanced variation of these components. Although their operating principle remains the same as manually operated valves, the opening and closing of the flow occur through an electric controller. Pneumatically operated wafer ball valves are the most reliable among all types. In their case, the pneumatic system is responsible for opening and closing the flow. They find application in installations involving gases or pressurized air.

Wafer ball valve – application

Wafer ball valves are most commonly used in the industry. Primarily, they serve to shut off or allow flow through a network. A wafer ball valve is a reliable isolation element for almost any installation. These valves are often installed in highly demanding environments, such as networks conveying gases or pressurized fluids. They are frequently employed in power generation for gas supply or exhaust installations. Other areas of application for these valves include processing, gas distribution, district heating, and hydraulic systems.