Globe Valves

Globe valves are a part of many water and steam installations. Their use allows for the regulation of water, steam, and other media. The globe valve itself consists of several important elements that ensure proper sealing of the installation to prevent leaks and enable the safe operation of the entire system.

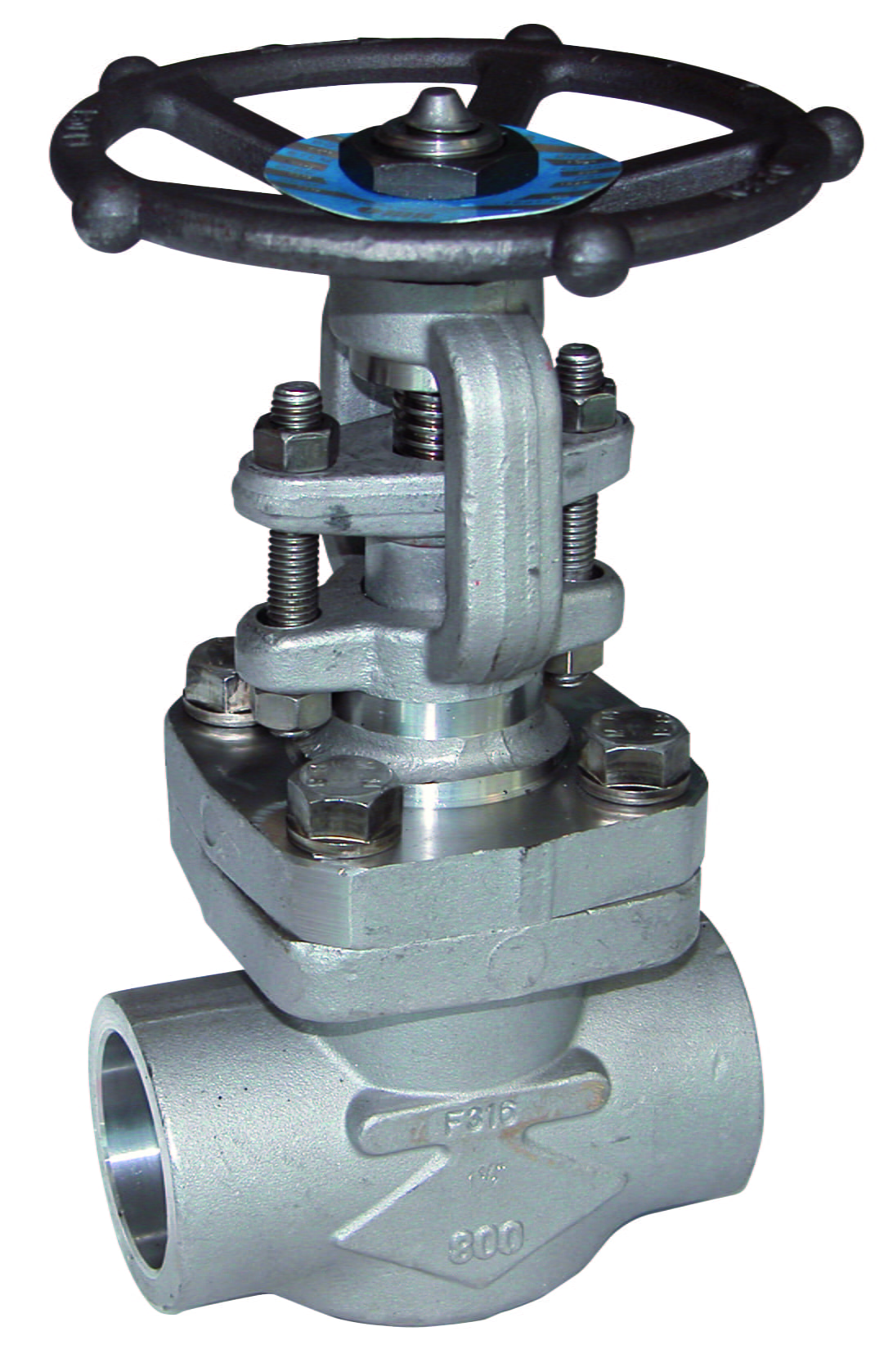

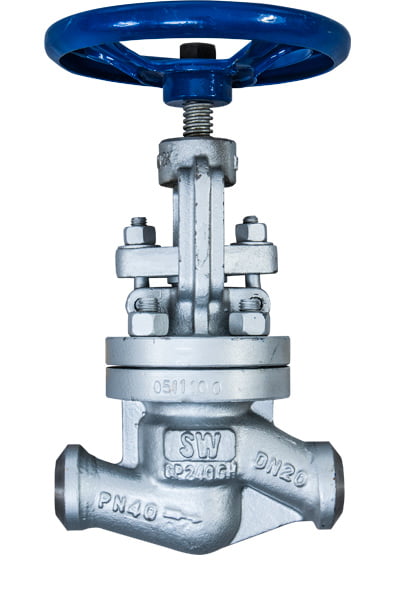

Construction of a Globe Valve

The construction specifics of a globe valve primarily depend on the type and intended use of the product. Globe valves for cold water are usually equipped with rubber seals – components that don’t require exceptionally high resistance and ensure smooth operation with convenient flow and safe closure of the supply. For hot water, globe valves with brass heads and Teflon sealing are used, as well as metal-to-metal sealing. The use of such materials involves their high resistance to contact with substances at high temperatures.

Globe valves for steam have metal-to-metal sealing. Precision machining of the sealing surfaces allows for maintaining 100% tightness in accordance with the EN12266-1 standard.

Globe valves for water are available in various sizes. In homes and apartments, the most common models have a diameter of 1/2 inch (DN 15), which perfectly fits standard water installations. When choosing a valve, it’s essential to carefully consider the pipe dimensions to ensure the safe operation of the entire system. Often used solutions also include 1-inch (DN 25) or 3/4-inch (DN 20) valves, although globe valves reaching up to 16 inches (DN 400) in diameter can also be found. Special heads can be purchased for these types of elements, enabling flawless operation and precise regulation. They are often selected separately, tailored to the specific element needed.

Globe Valve – principle of operation

Every globe valve is constructed from several parts that work together to ensure its proper functionality. Within the valve body, there is a socket containing a sealing element. The operating principle remains the same for valves with rubber seals, metallic ones, or those mounted on a movable stem. The appropriate construction of the valve, along with properly chosen sealing elements, ensures safety and convenience in the use of water installations.

What characteristics should globe valves have?

Globe valves for water are used to enable the regulation of water flow within an installation. These products must, therefore, feature high resistance to external factors, mechanical damage, and temperature changes. Another crucial aspect is ease of installation – a classic globe valve should easily connect to the pipe during installation.

Before purchasing, it’s also essential to thoroughly verify the layout of the installation and the pipe diameter. For water installations in homes, both straight and angled globe valves are recommended. Within our range, we offer valves made of gray cast iron, ductile cast iron, carbon steel, and stainless steel, which are used in installations requiring exceptional durability and resistance. Such products require welding or have flange connections, making them most commonly found in industrial equipment.

Globe Valve selection

Before purchasing a globe valve, it’s important to establish several key pieces of information that will facilitate the selection of the appropriate product. The most crucial factors are the type, temperature, and pressure of the medium flowing through the installation – for cold water, a standard model with a rubber seal is sufficient. Hot water, on the other hand, requires stronger valves, such as copper, metal, steel, or those with Teflon sealing. If a globe valve with a rubber seal were connected to hot water, the product could quickly lose its properties, leading to leaks and potentially even flooding of a residence or building.