Stainless steel knife gate valves for sewage treatment

Description: monoblock body, rising or non-rising stem, single or double-sealed on one or both sides

Diameters: DN 50 – DN 1000

Connection: Wafer and LUG

Pressure: PN 6 – 25

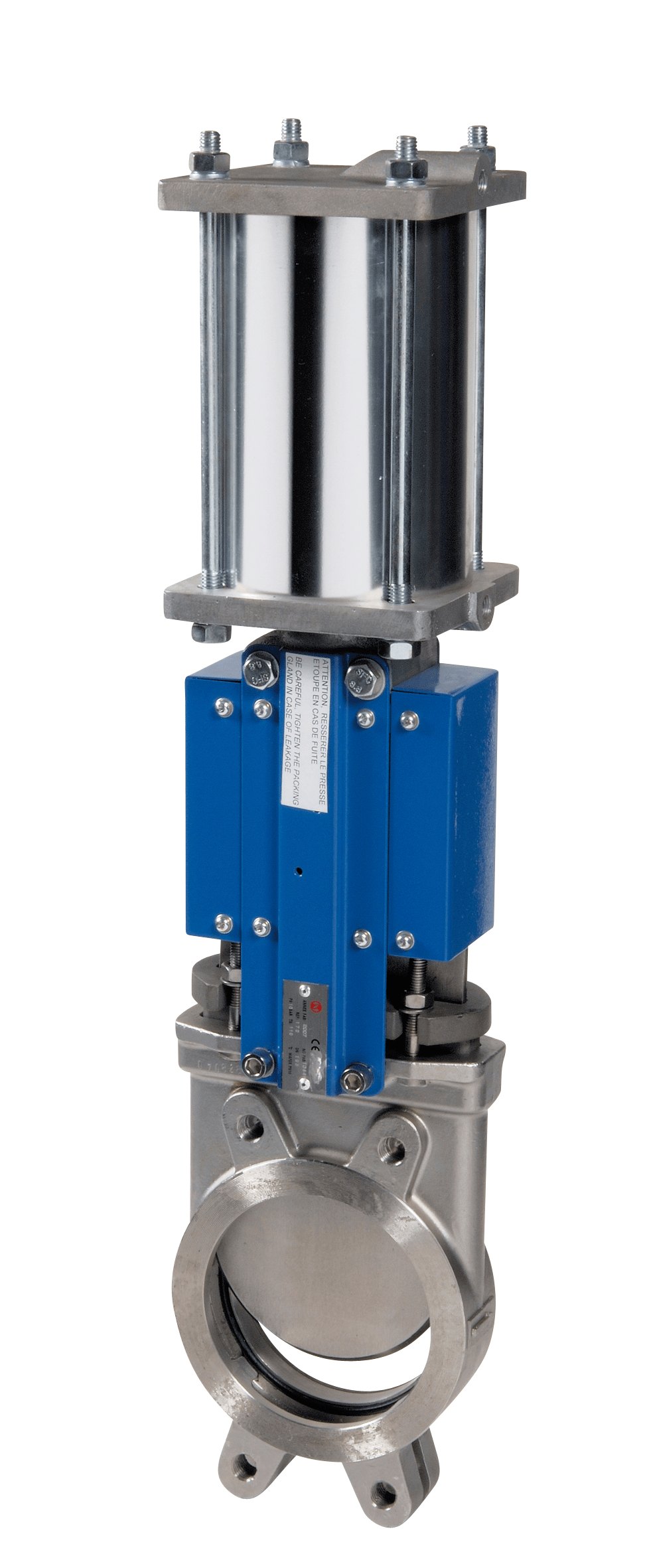

Body: Gray cast iron GG25, ductile iron GGG40, stainless steel CF8M, carbon steel GP240GH, other materials available upon request

Knife: stainless steel AISI 304, stainless steel AISI 316

Seal: EPDM, NBR, Metal, Viton, PTFE, Silicone

Packing: cotton impregnated with PTFE, PTFE, graphite

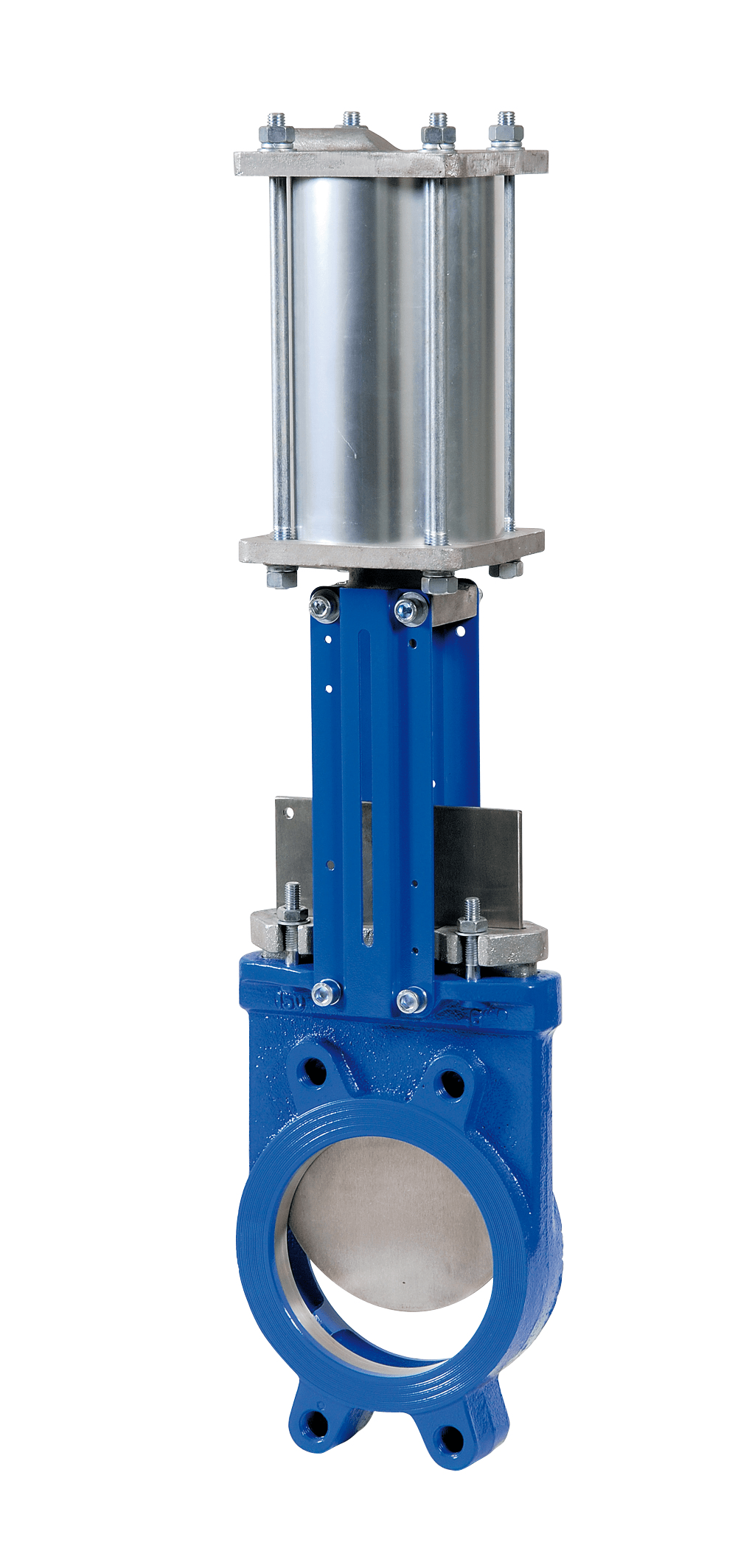

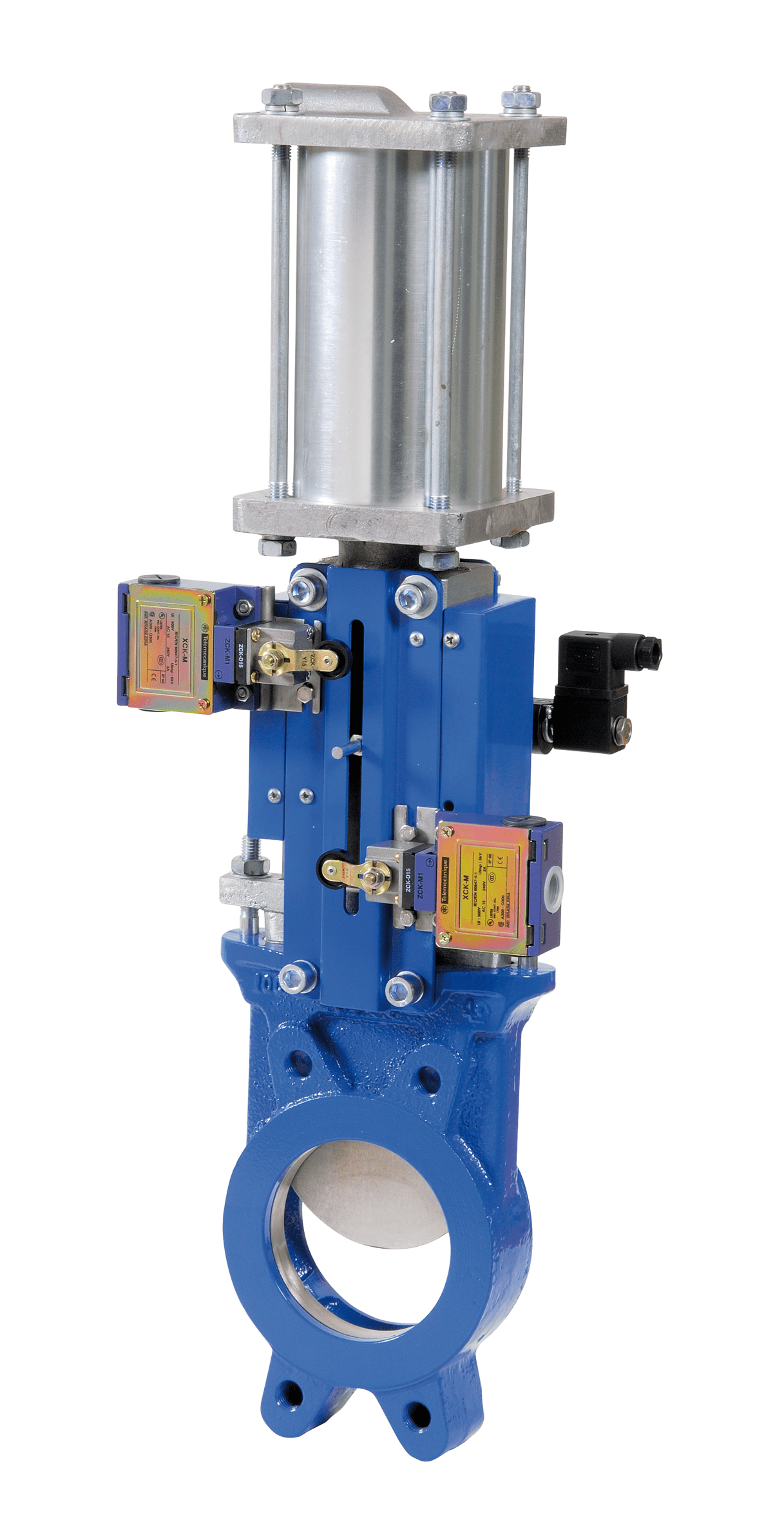

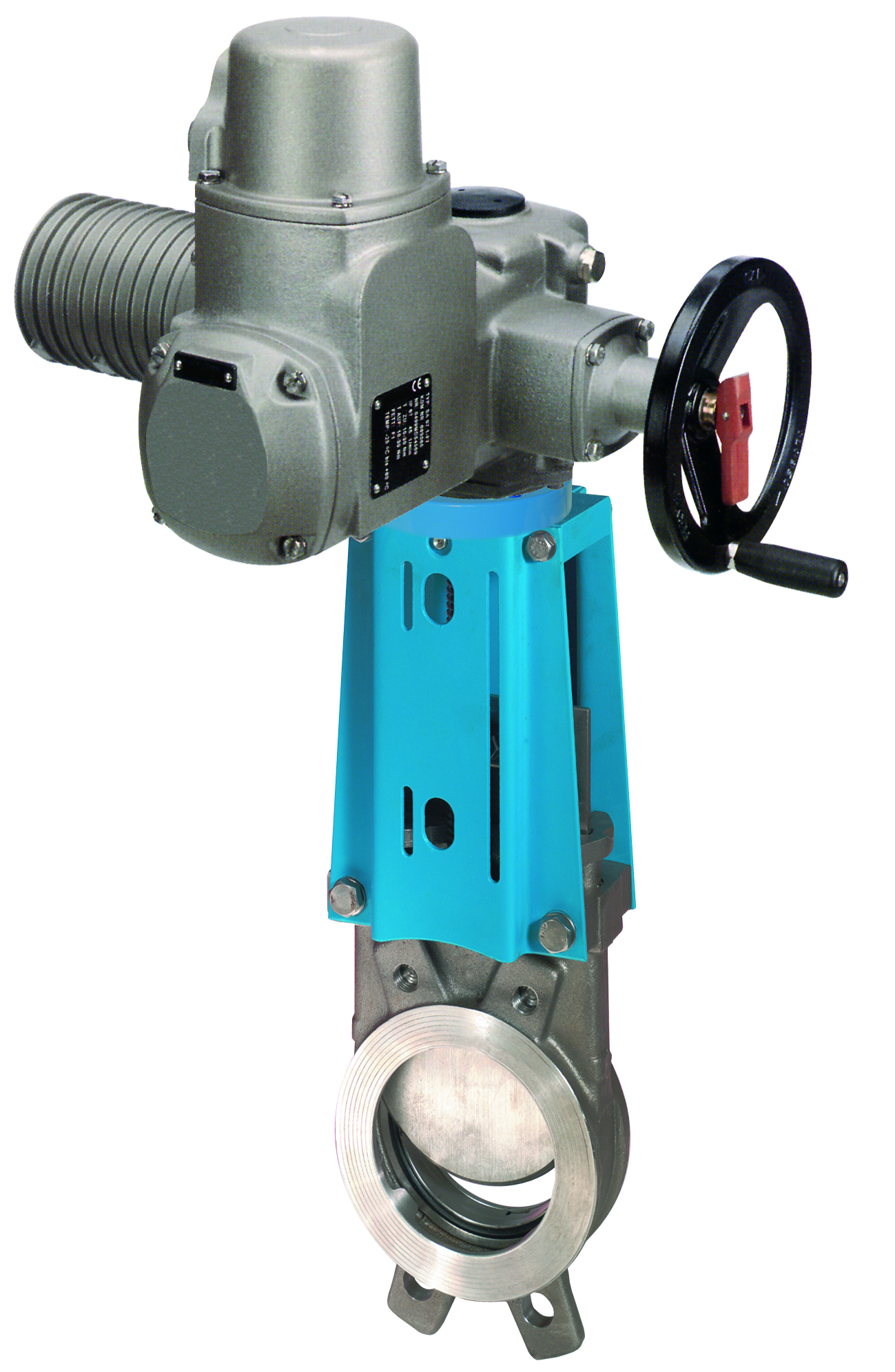

Drive: handwheel, pneumatic drive, electric drive

Special version: deflector, scraper, V-port, cleaning holes in the body, tight cover

Usage: paper industry, power plants, sewage treatment plants, food industry

Producers: GTM Process Valves, Orbinox, Zubi, CMO, Jafar, Stafsjo, Sferaco

In today’s era where technology and innovation drive industrial development, quality and reliability stand as key elements of success. In the industrial valve sector, where precision and durability are paramount, stainless steel knife gate valves for sewage stand out as an integral component in many advanced systems. GTM Process Valves, a leading manufacturer and direct importer of industrial valves from various parts of the world, takes pride in offering top-quality products. Crafted with meticulous attention to detail, these articles blend traditional craftsmanship with modern technologies, ensuring their reliability and long lifespan.

Technical aspects of the product

The stainless steel knife gate valves offered by GTM Process Valves feature a wide range of diameters, ranging from DN 50 up to DN 1000, allowing for versatile applications in various industrial systems. One of the key technical aspects is the monoblock body, providing exceptional strength and durability to the product. Additionally, the use of a rising or non-rising stem enables precise control of fluid flow.

Materials used in manufacturing these valves, such as gray cast iron GG25, ductile iron GGG40, stainless steel CF8M, or carbon cast steel GP240GH, ensure excellent corrosion resistance and product longevity. The blade, made of high-quality stainless steel AISI 304 or stainless steel AISI 316, guarantees precise and clean cutting, which is crucial for the efficient operation of the valve.

Sealing, available in various materials like EPDM, NBR, Metal, Viton, PTFE, or Silicone, ensures excellent sealing and resistance to different chemical environments. The packing, made of impregnated PTFE cotton, PTFE, or graphite, further enhances the reliability of the product

Versatile applications of the stainless steel sewage knife gate valve

In the industrial environment where effectiveness and efficiency are key to success, stainless steel knife gate valves for sewage play a crucial role across multiple sectors. In the paper industry, where fluid flow control is essential for high-quality paper production, these valves ensure precise and reliable operation. In power plants, where safety and efficiency take priority, these valves provide optimal water and fluid flow. In wastewater treatment plants, where water purity is paramount, stainless steel knife gate valves assist in effectively managing sewage flow. Additionally, in the food industry, where hygiene and product quality are paramount, these valves ensure safe fluid flow. With special components like deflectors, scrapers, or cleaning holes in the body, these valves are highly versatile and adaptable to various industrial needs. Their reliability and durability make them an integral part of many advanced industrial systems.

Quality and reliability are key in the realm of industrial valves. Therefore, GTM Process Valves, as a manufacturer and direct importer of industrial valves, takes pride in offering top-quality stainless steel knife gate valves for sewage. Thanks to their technical aspects and versatility, these valves become an essential element in numerous industrial sectors.

Our strength lies in maintaining Poland’s largest inventory of knife gate valves, not only in basic ductile iron executions but also in a wide range of acid-resistant stainless steel CF8M variations.