Wells

In various industrial sectors, pressure vessels constructed from specially designed, tailored components are often utilized. Among them are wells, which constitute an important part of the vessel. Their task is to ensure the appropriate pressure throughout the structure, which crucially affects the system’s operation. In the GTM Process Valves assortment, there are steel wells available in various shapes, allowing for easy selection of the best solution for a given installation. Before making a choice, it’s worth familiarizing oneself with the characteristics of this component and its various variants

Stainless Steel Wells

Wells are extremely important components of any pressure vessel. They are primarily responsible for maintaining the appropriate pressure within the structure, allowing the installation to maintain correct operational parameters. They can be made from various materials, but the most popular choice is stainless steel, which provides high strength combined with corrosion-resistant properties. It’s worth noting that the bottom of a pressure vessel should always be made from the highest quality materials. Damage to it could result not only in the destruction of the entire installation but also in endangering the safety of workers.

The shape of the well must be properly matched to the nominal pressure, so the parameters of the bottom should be considered when preparing it. One example of using such elements is fire extinguishers, where the bottom is made of sheet metal with a thickness corresponding to the pressure inside the extinguisher. The same principle applies to designing wells for industrial pressure vessels.

Steel Wells

Steel wells are one of the most popular variants of this element used in industry. What makes them so widely used? It’s primarily the unique properties of steel – this material provides high durability and resistance to potentially harmful effects of high pressure. Additionally, steel wells often feature acid resistance and anti-corrosive properties, which are particularly important in the case of pressure vessels. This is because the highest pressure exerted by the working fluid occurs at the bottom, where the wells is installed.

Ellipsoidal Wells

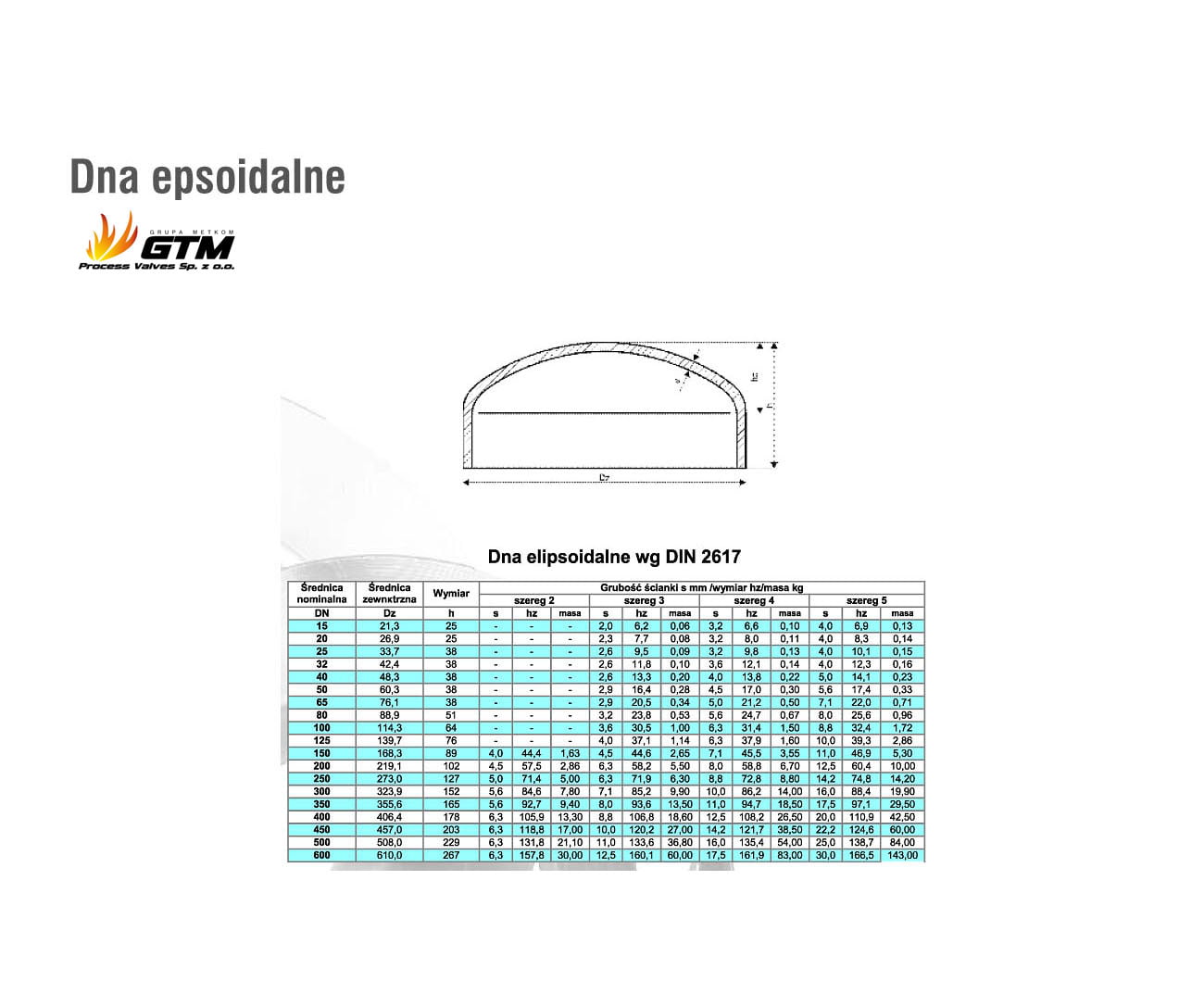

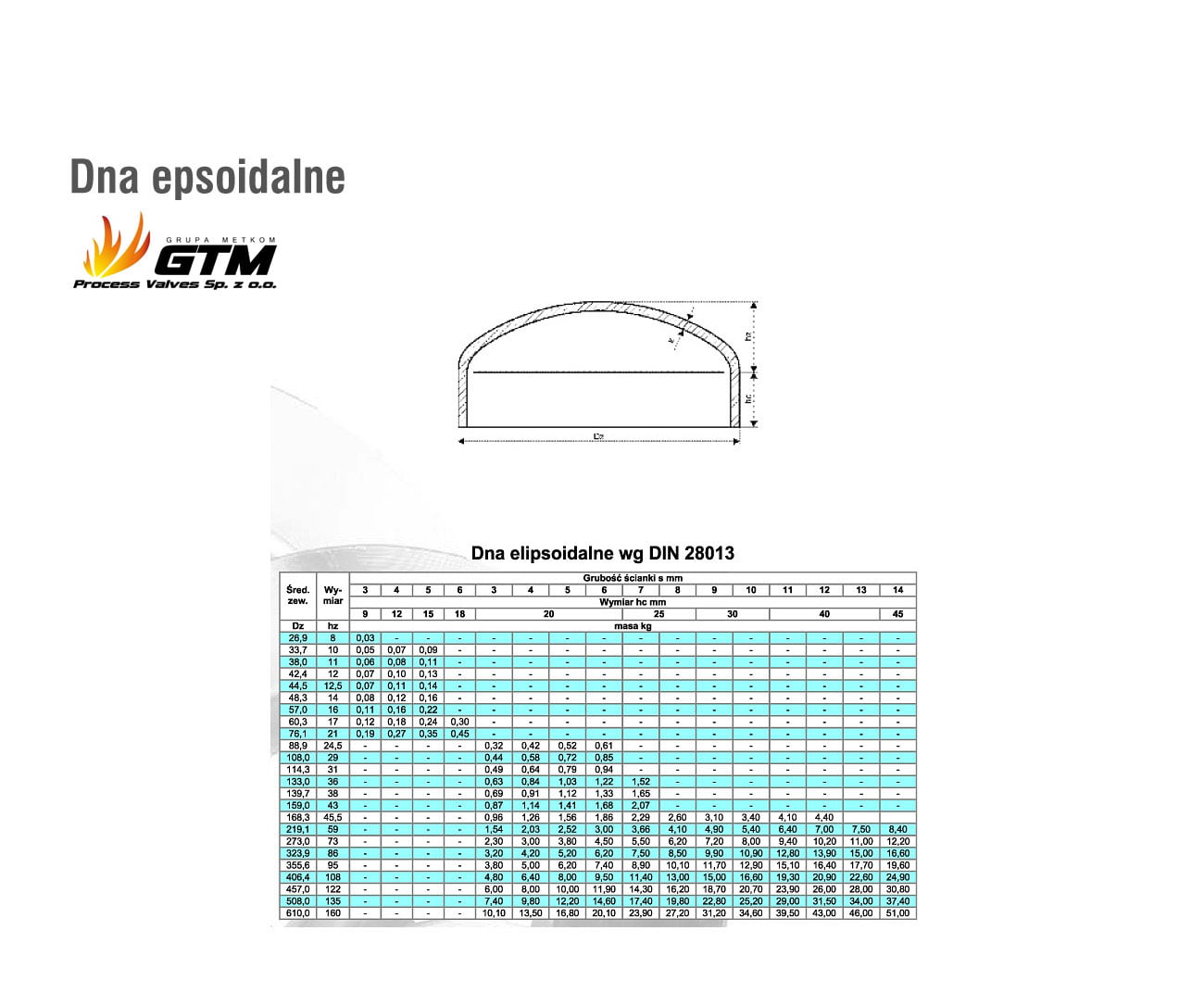

The shape of wells depends primarily on their intended use – furthermore, the construction characteristics are directly related to the parameters of the head. In the case of ellipsoidal wells, guidelines according to DIN 28013 are followed. This type of head is mostly made of steel, but models prepared from steel-like materials can also be found, aiming to have similar properties. The most important aspect is maintaining corrosion resistance and high pressure capabilities.

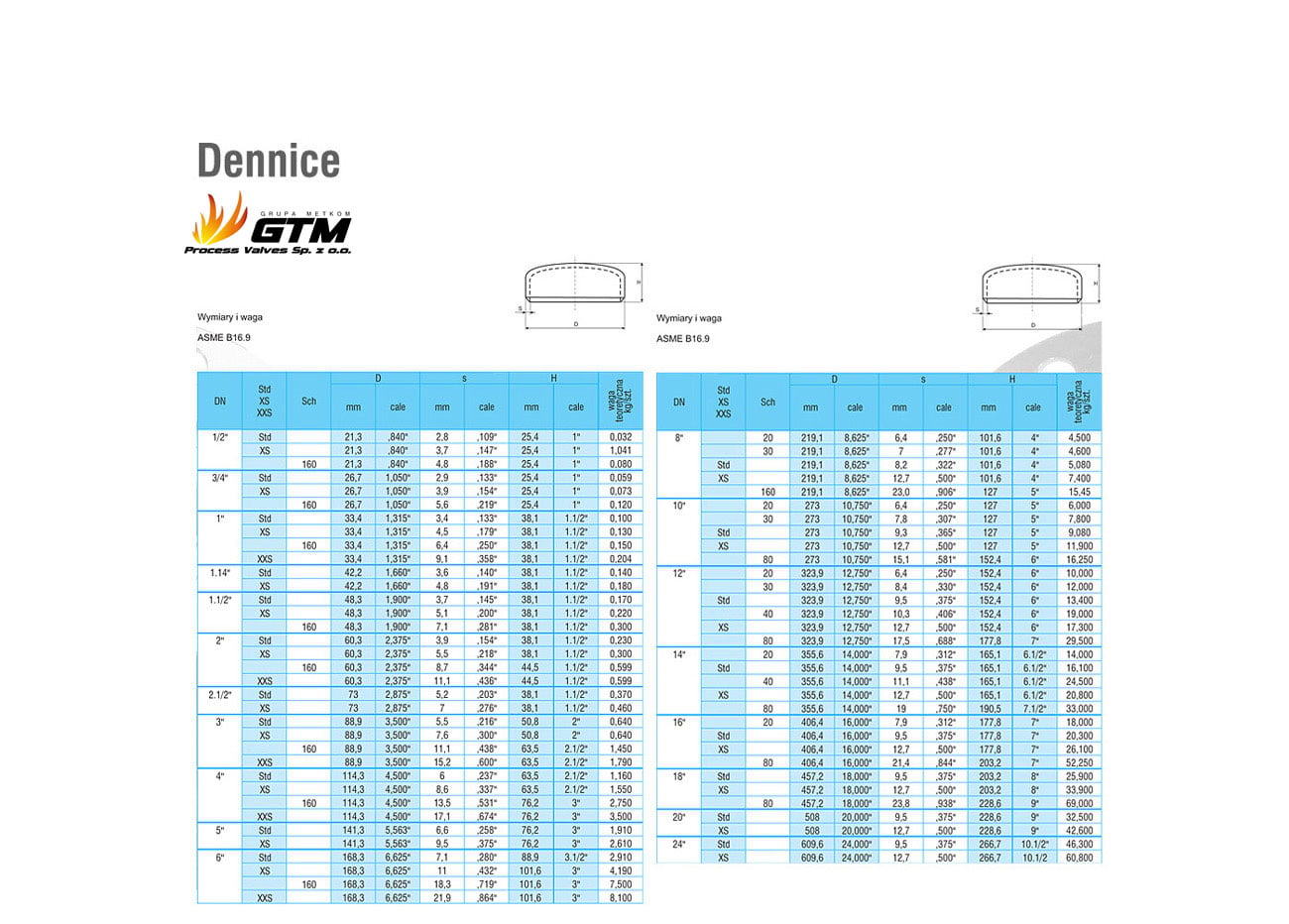

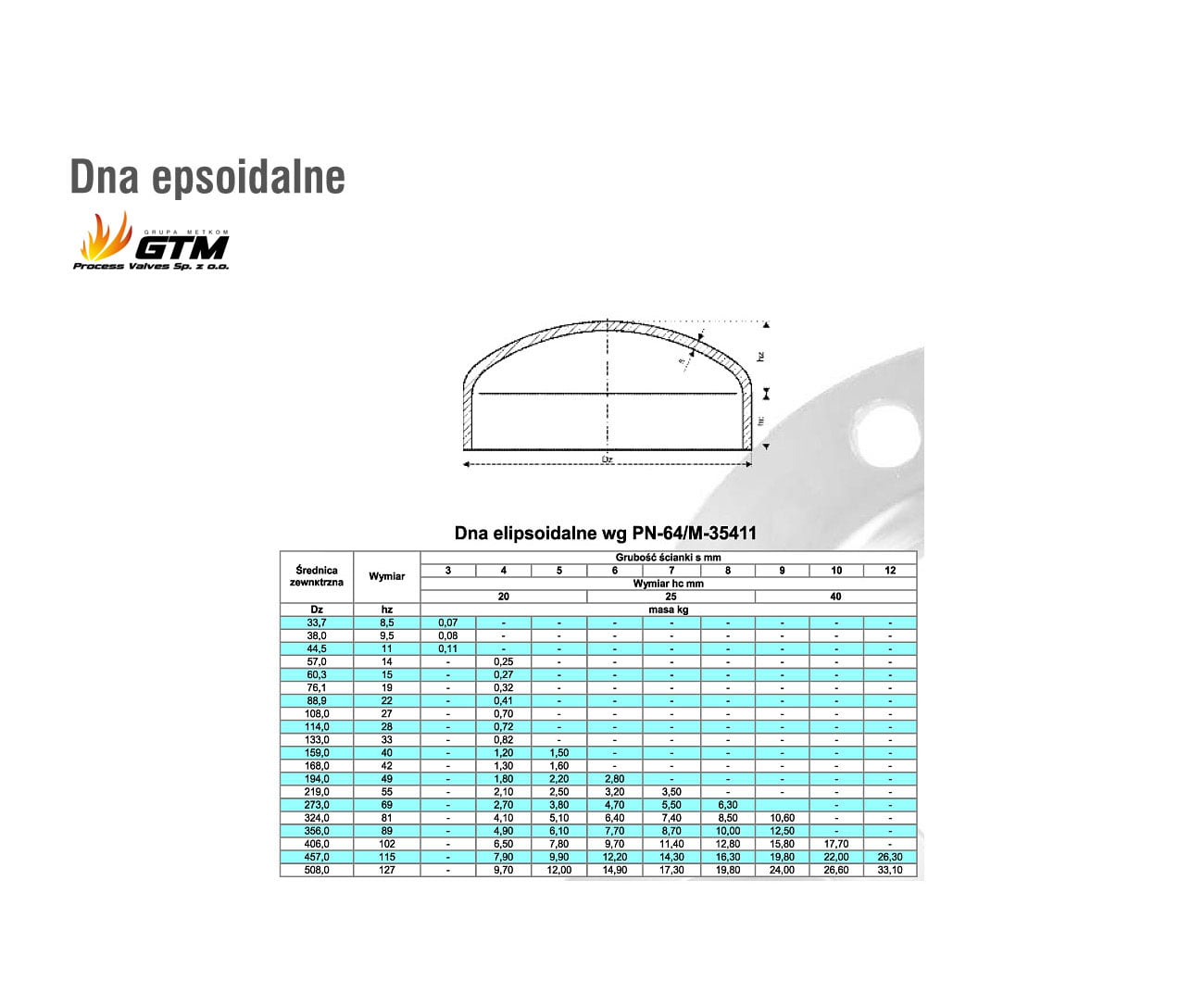

Wells – sizes

The dimensions of wells depend primarily on the parameters of the pressure vessel – the head must be constructed according to the requirements of the entire structure. The nominal pressure also plays a significant role. In the GTM Process Valves offer, solutions with diameters ranging from 1/2″ to 24″ can be found, and for ellipsoidal shapes, from 33.7 mm to over 600 mm.

Steel Wells – producer

The GTM Process Valves store offers a wide selection of various steel dished heads, whose construction varies depending on the parameters of the vessel and the nominal pressure. All models in our range are made from high-quality materials, ensuring durability and efficiency.