PTFE Butterfly Valves

The butterfly valve is one of the most essential tools used in various production processes. Teflon models are suitable for processes related to chemistry, petrochemistry, as well as water treatment or wastewater purification. GTM Process Valves offer a wide range of solutions, such as PTFE butterfly valves that differ primarily in the disc material or types of drives, enabling the automation of production lines. The disc material includes stainless steel 1.4408 or steel coated with PTFE or PFA.

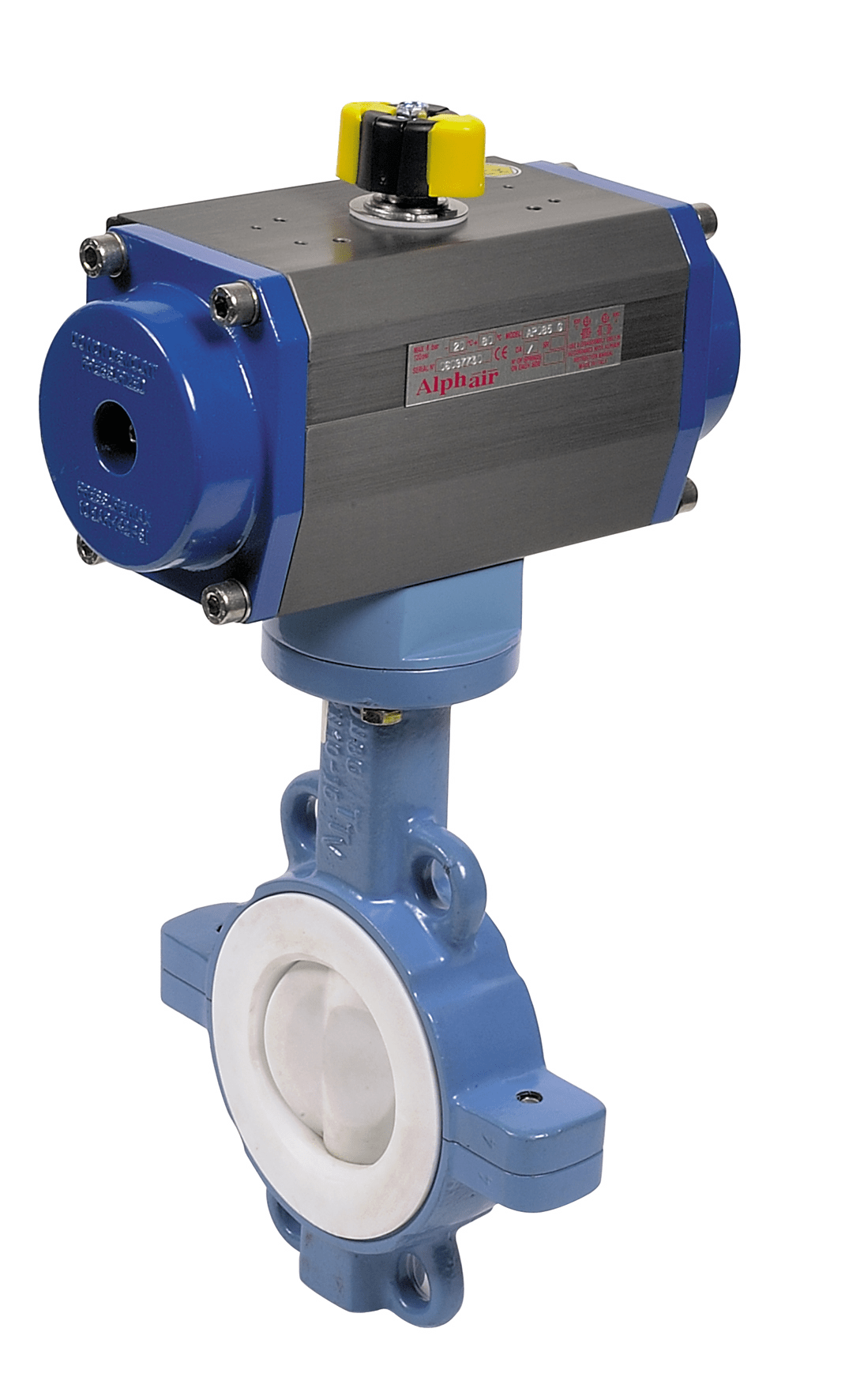

PTFE Butterfly Valve with pneumatic and electric actuator

Description: butterfly valve with centrally mounted disc, Teflon seal

Connection: wafer and LUG type between flanges, flanged

Diameters: DN 32 – DN 900

Pressure: PN 10

Body: ductile cast iron GGG 40/50, acid-resistant steel

Disc: stainless steel, PTFE-coated steel, PFA

Sealing: PTFE

Actuator: hand lever, gear-box, pneumatic drive, electric drive

Certyfication: CE marking, PZH certificate, 3.1 EN 10204 certificate, others

Usage: chemistry, petrochemistry

Producers: InterApp, Ebro Armaturen, Bray, Ghibson

A PTFE butterfly valve

What makes the Teflon butterfly valve so widely applicable within production processes across various industries? Primarily, it’s the capabilities of these solutions that focus on automating production lines, thereby significantly improving processes. Additionally, attention should be paid to its high durability resulting from the use of sealing made of PTFE or PFA.

PTFE (polytetrafluoroethylene) is a material known for its high chemical resistance, often recognized as Teflon. It is incredibly resistant to chemicals and high temperatures while exhibiting very low friction, making it an ideal material for use in the chemical industry.

The Teflon butterfly valves in our offering stand out for their exceptional durability, allowing for long-term operation. Each valve of this type within GTM Process Valves’ assortment features a disc made of stainless steel or a disc coated with PTFE. Importantly, our clients can also opt for models with manual operation through a lever or with a worm gear. All our Teflon butterfly valves are marked with CE certificates and various approvals, including PZH or 3.1 EN 10204.

PTFE Sealed Teflon Butterfly Valves

A Teflon-coated PTFE butterfly valve is an ideal solution for automating production lines. An electric or pneumatic drive makes using the valve simple and comfortable. It’s also worth mentioning the disc, which directly regulates the flow. This element is made of high-quality materials such as stainless steel, steel coated with PTFE, and perfluoroalkoxy (PFA). This selection of materials ensures the utmost durability of this small component. Importantly, the entire valve is protected by a PTFE seal.

How do Teflon butterfly valves work?

The principle behind the operation of a Teflon butterfly valve is remarkably simple and involves adjusting the centrally positioned disc. In the case of Teflon valves, it’s also possible to regulate the flow rate. The regulating action works best within the range of 25% to 70% of the disc’s opening angle. However, this action should be performed with utmost caution due to the risk of damaging the disc. Our offerings encompass the best industrial valve solutions – feel free to explore GTM Process Valves’ range.