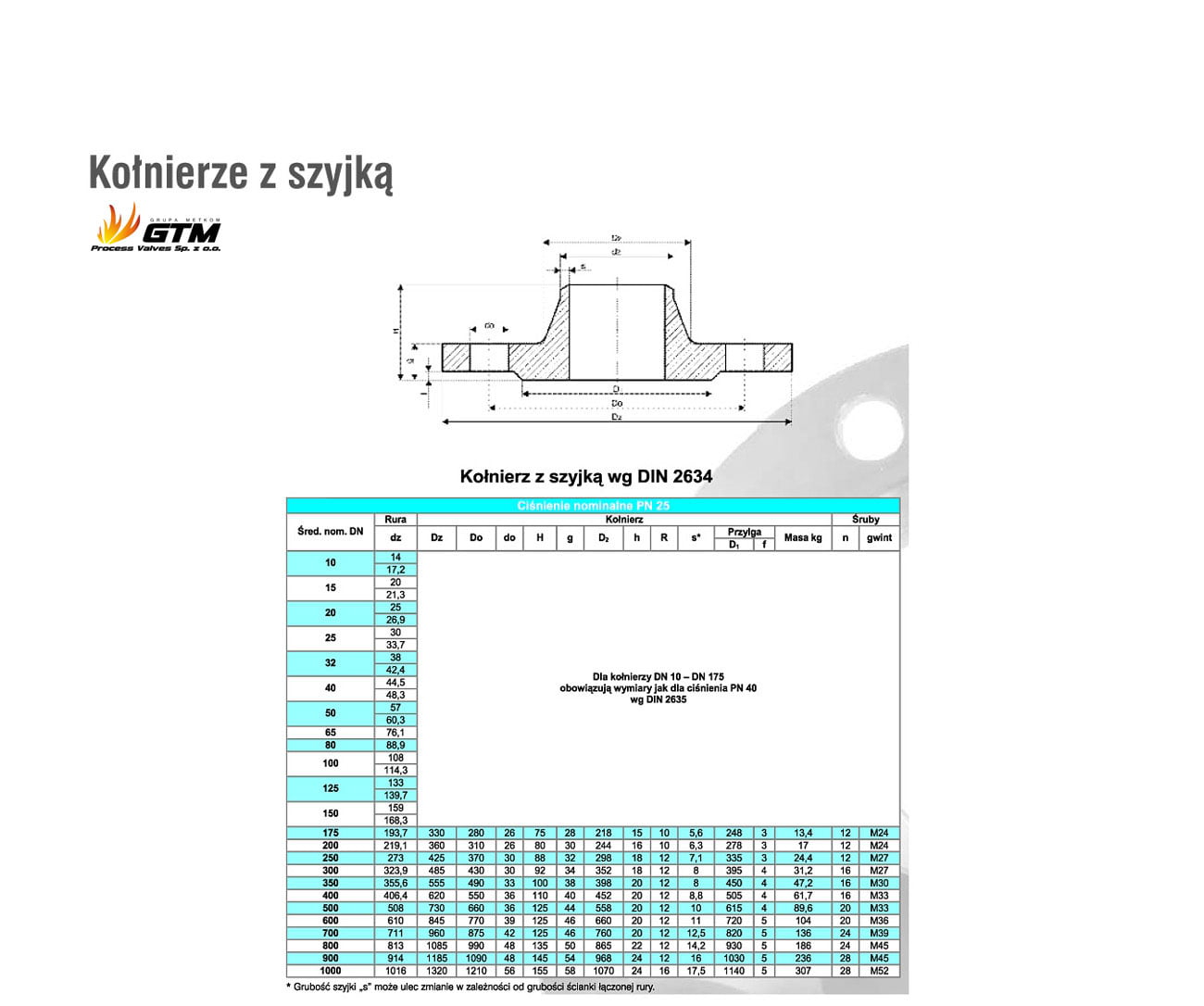

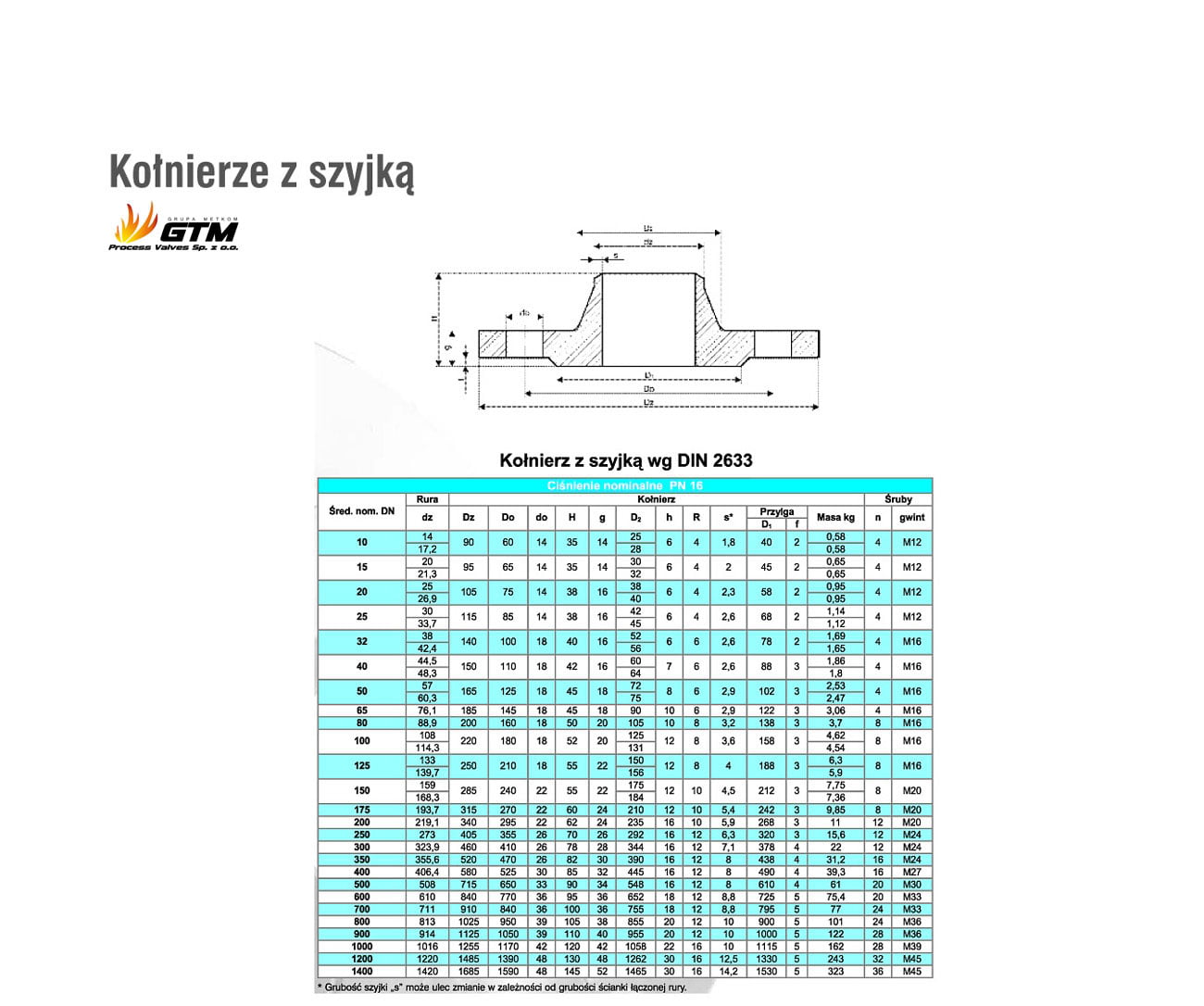

Steel Flanges with weld neck

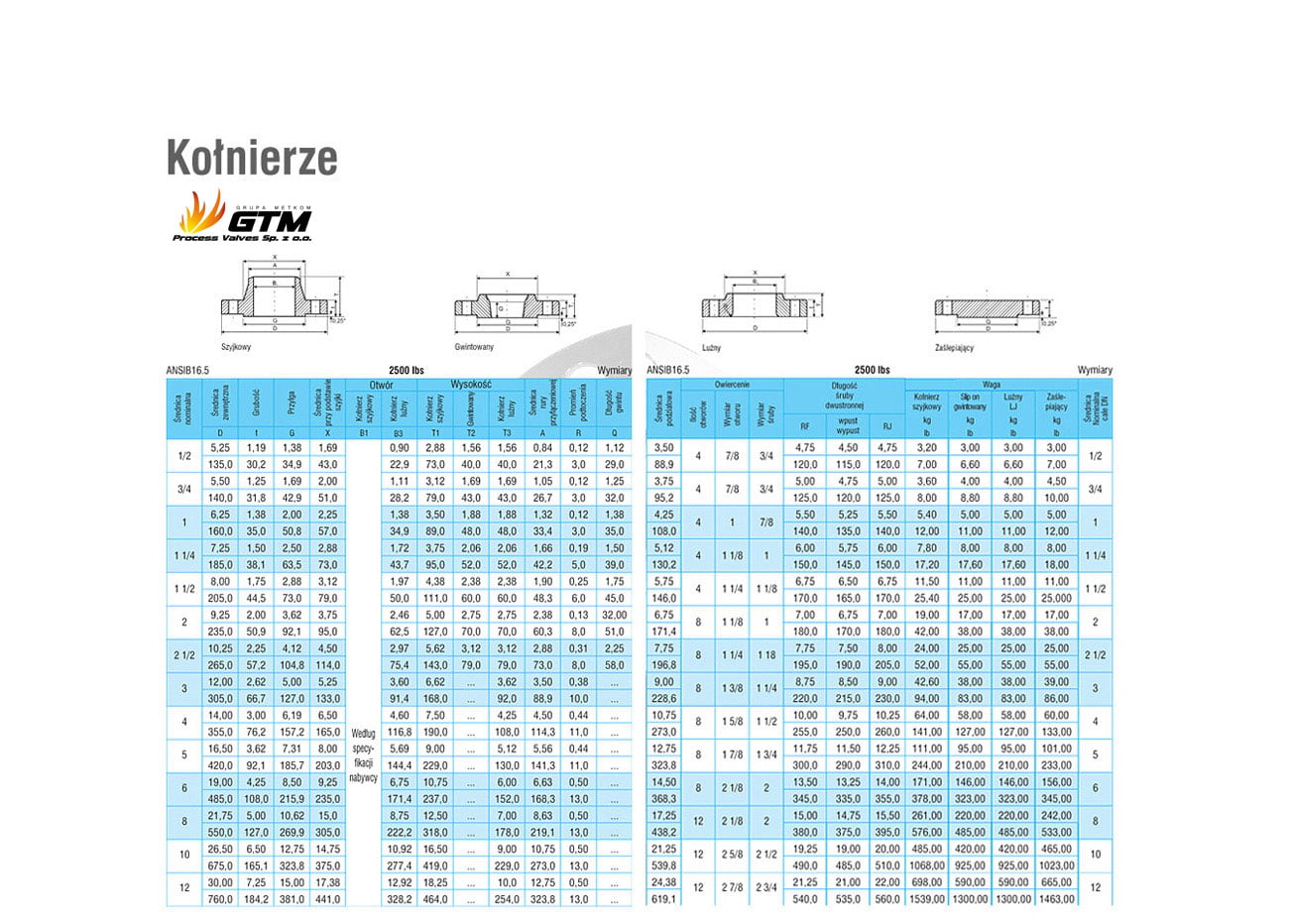

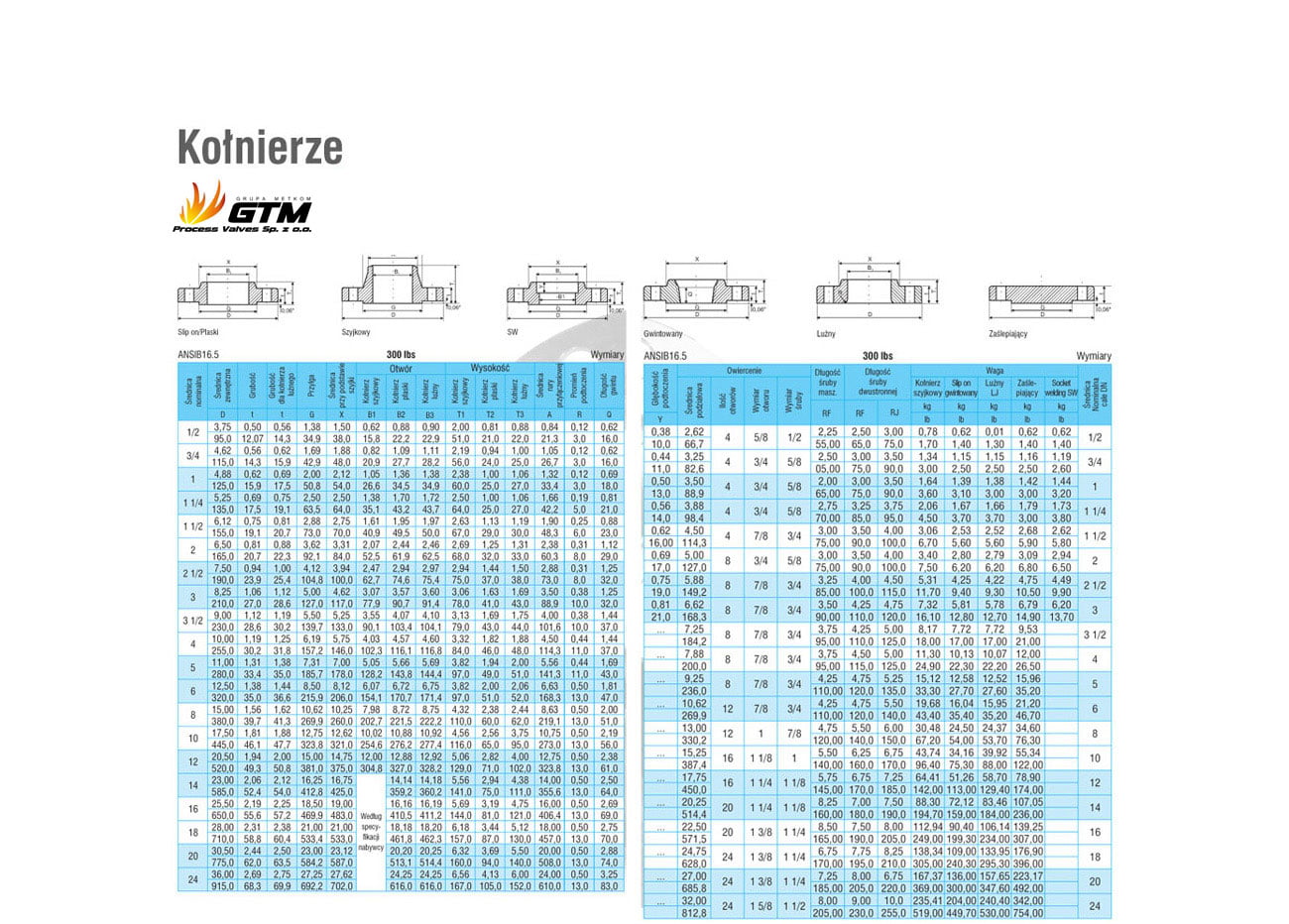

Steel flanges are an essential component in many piping systems and pipe installations. Their use enhances the functionality of the systems while also providing better security. With them, pipes and pipelines can be securely joined and connected to pressure vessels. Among the various types utilized, flat steel flanges and threaded steel flanges are the most prominent. These two types differ in their construction and installation, hence they find application in slightly different installations.

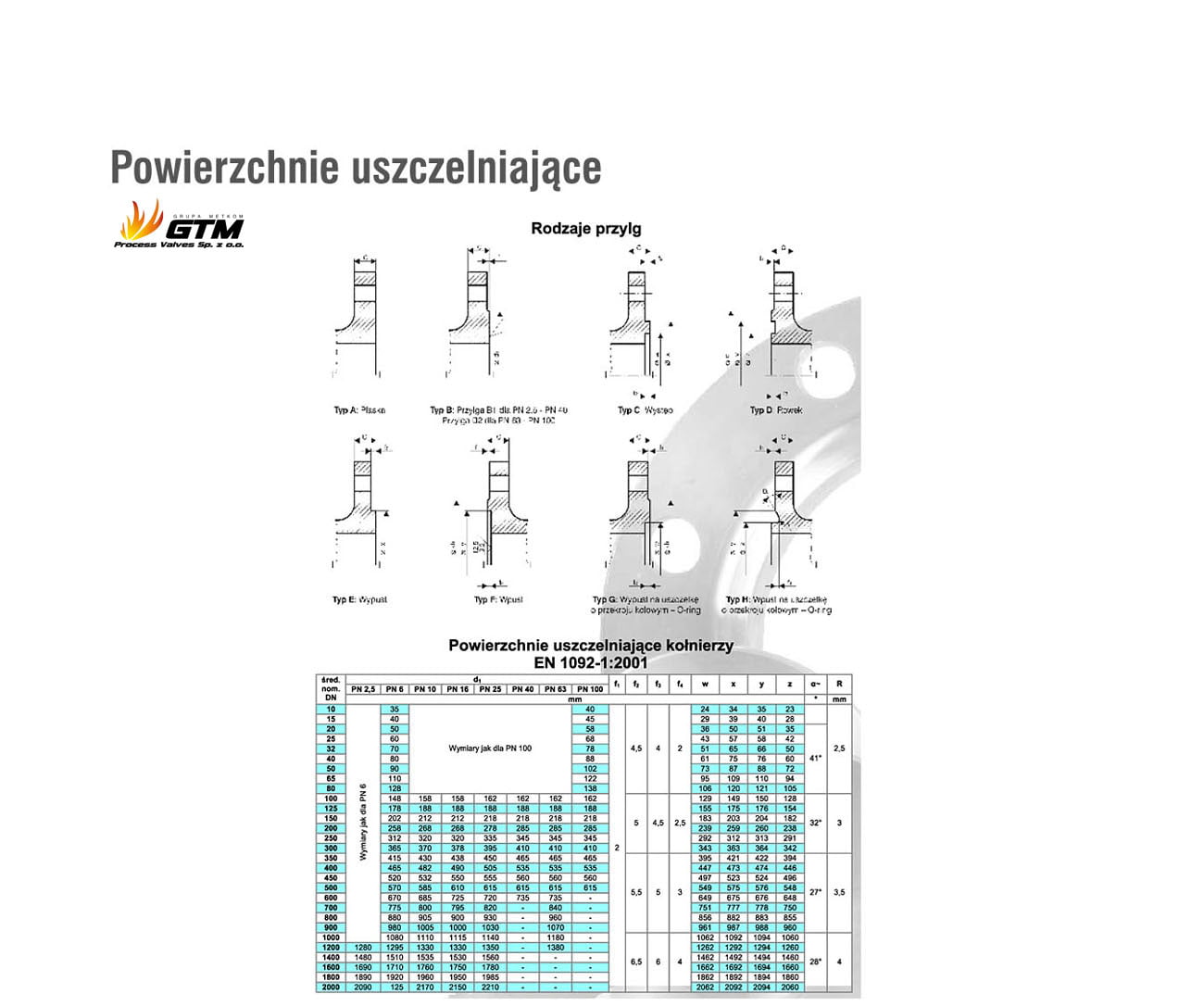

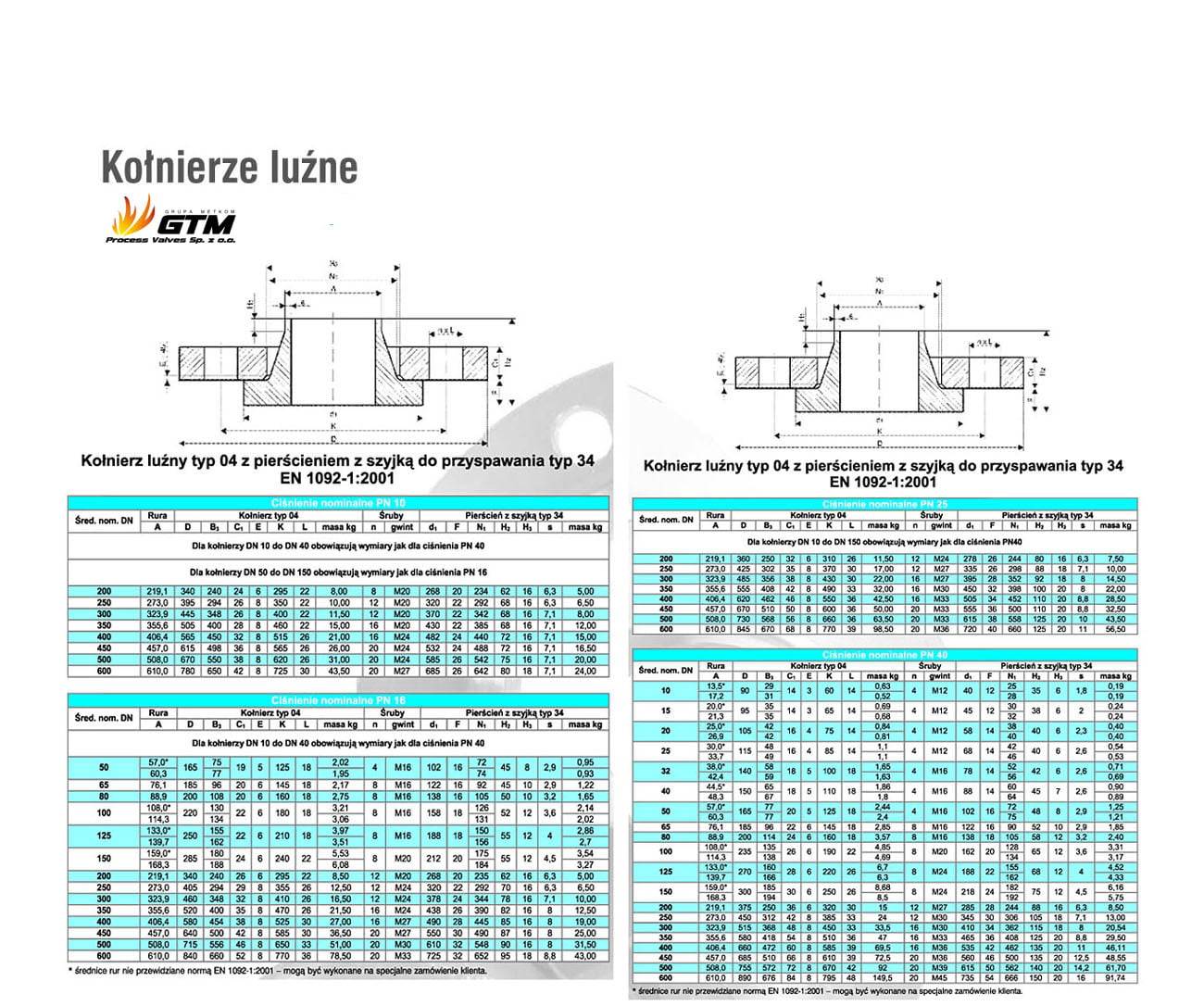

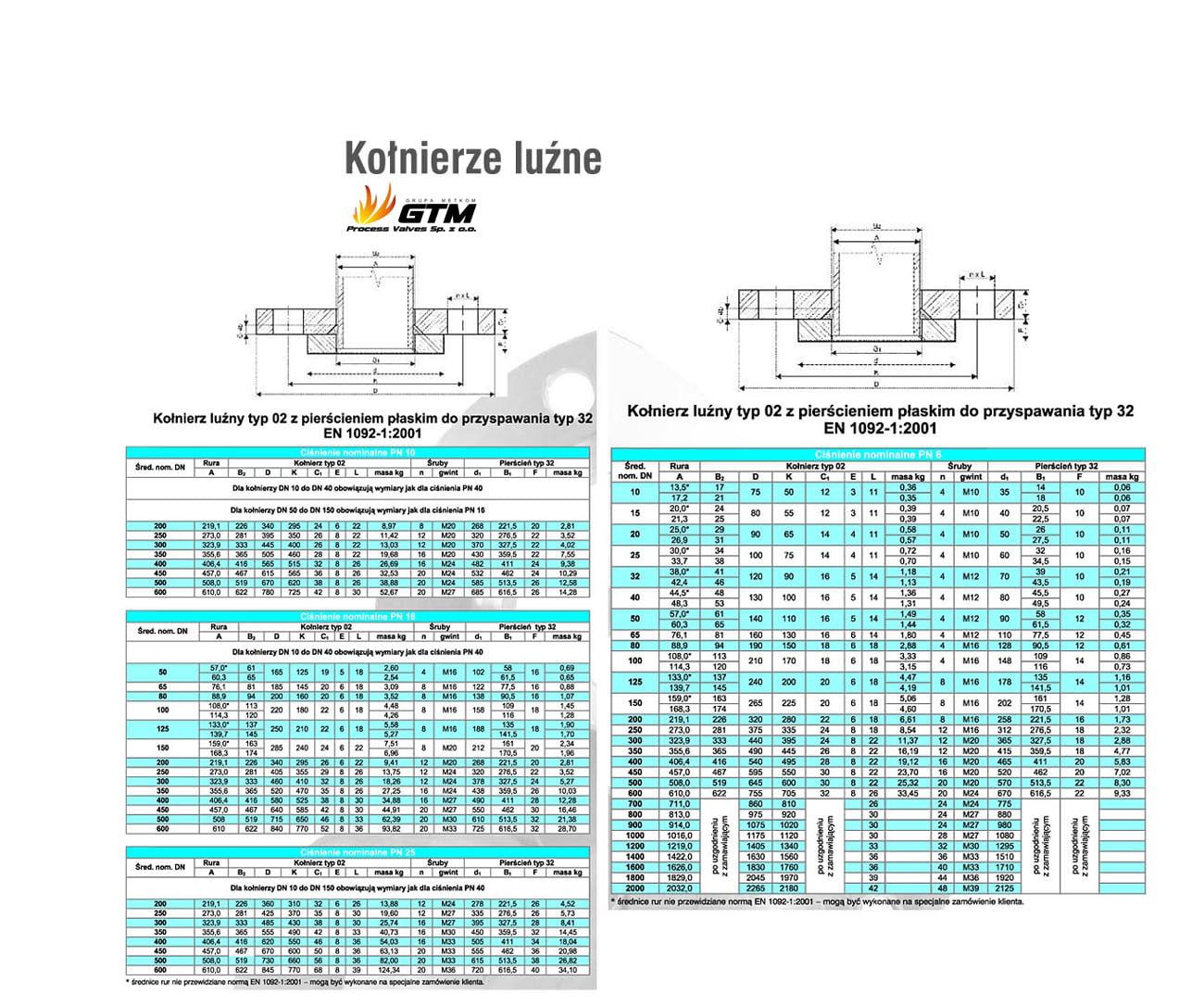

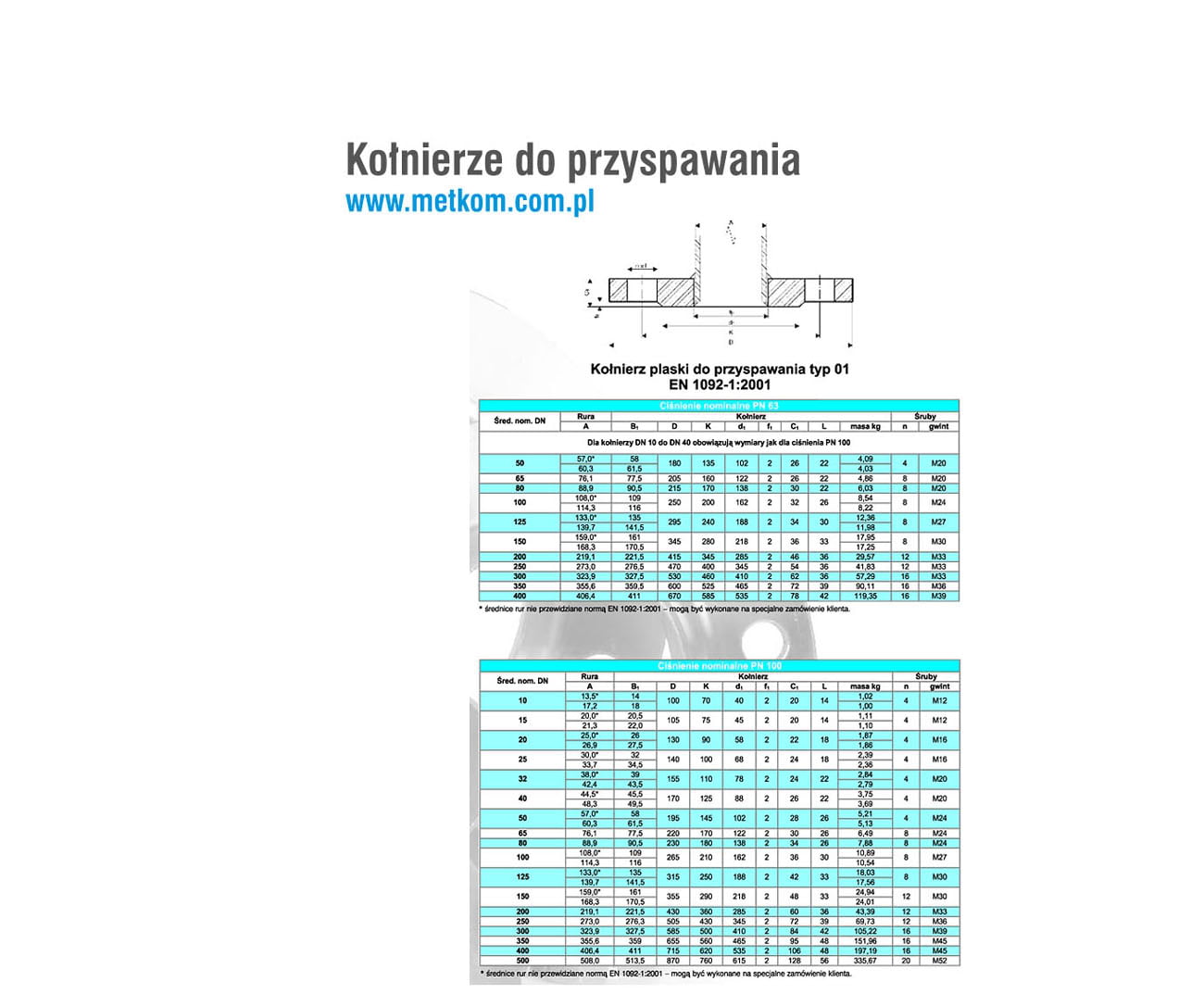

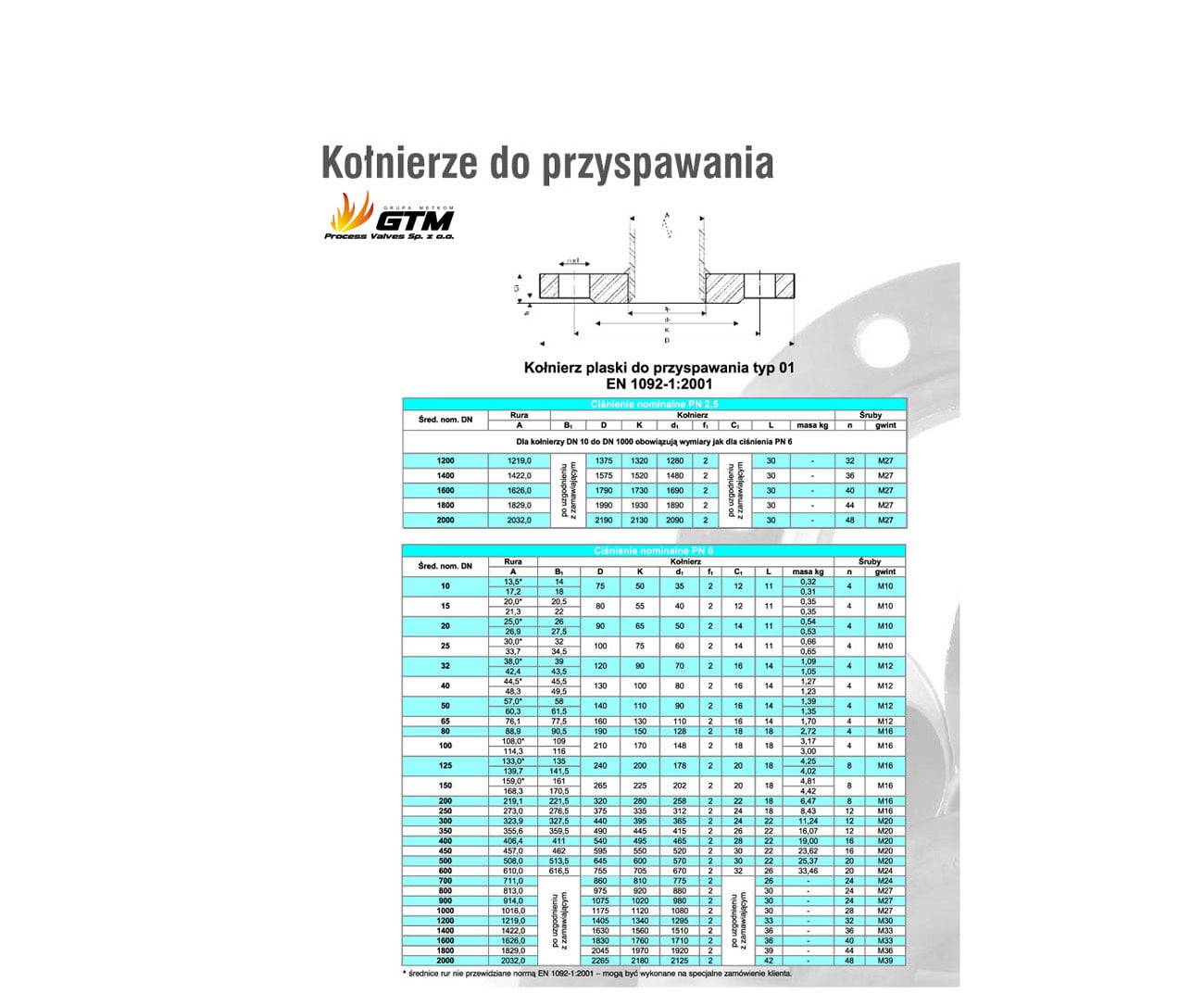

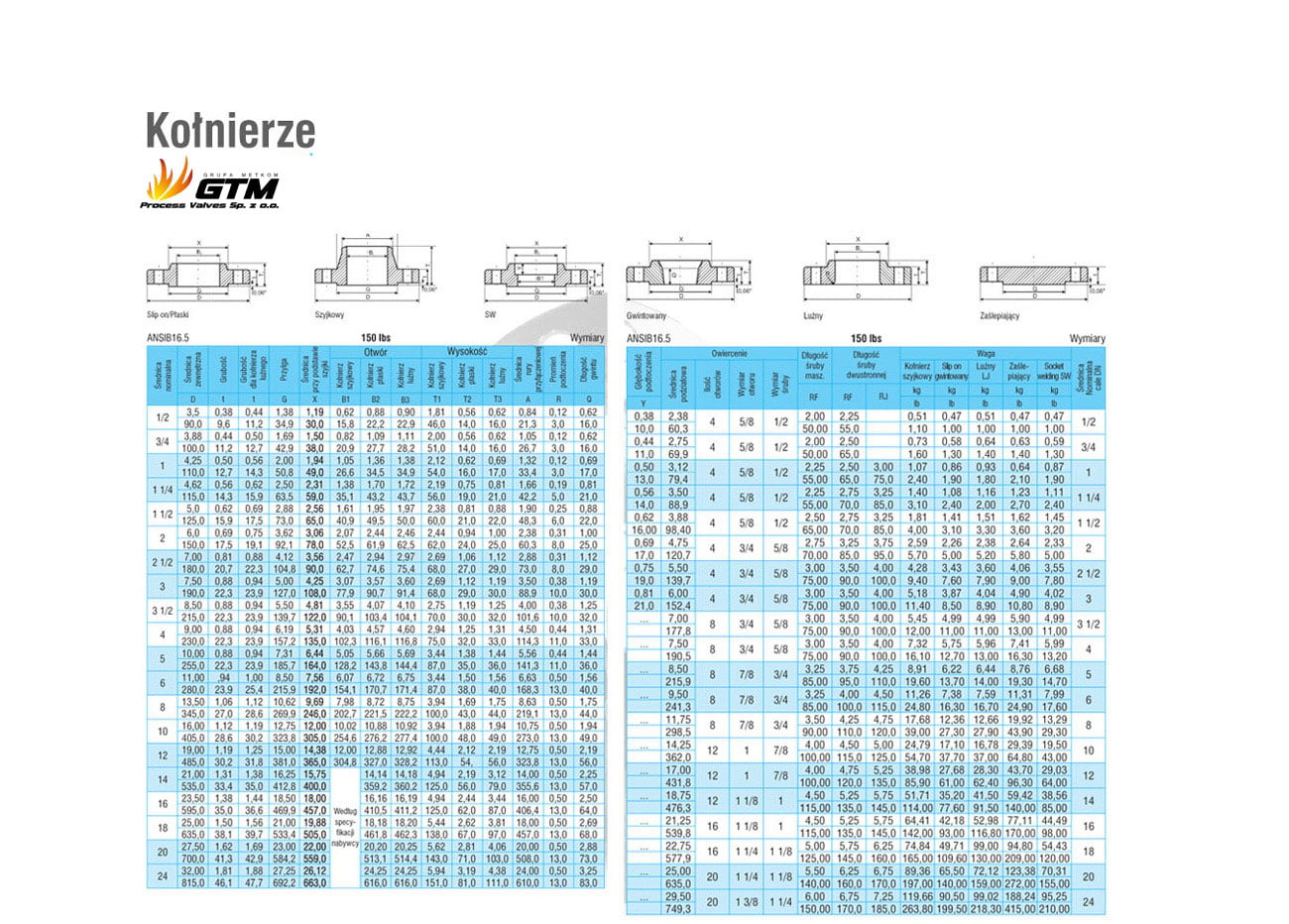

Steel flanges – dimensions and construction

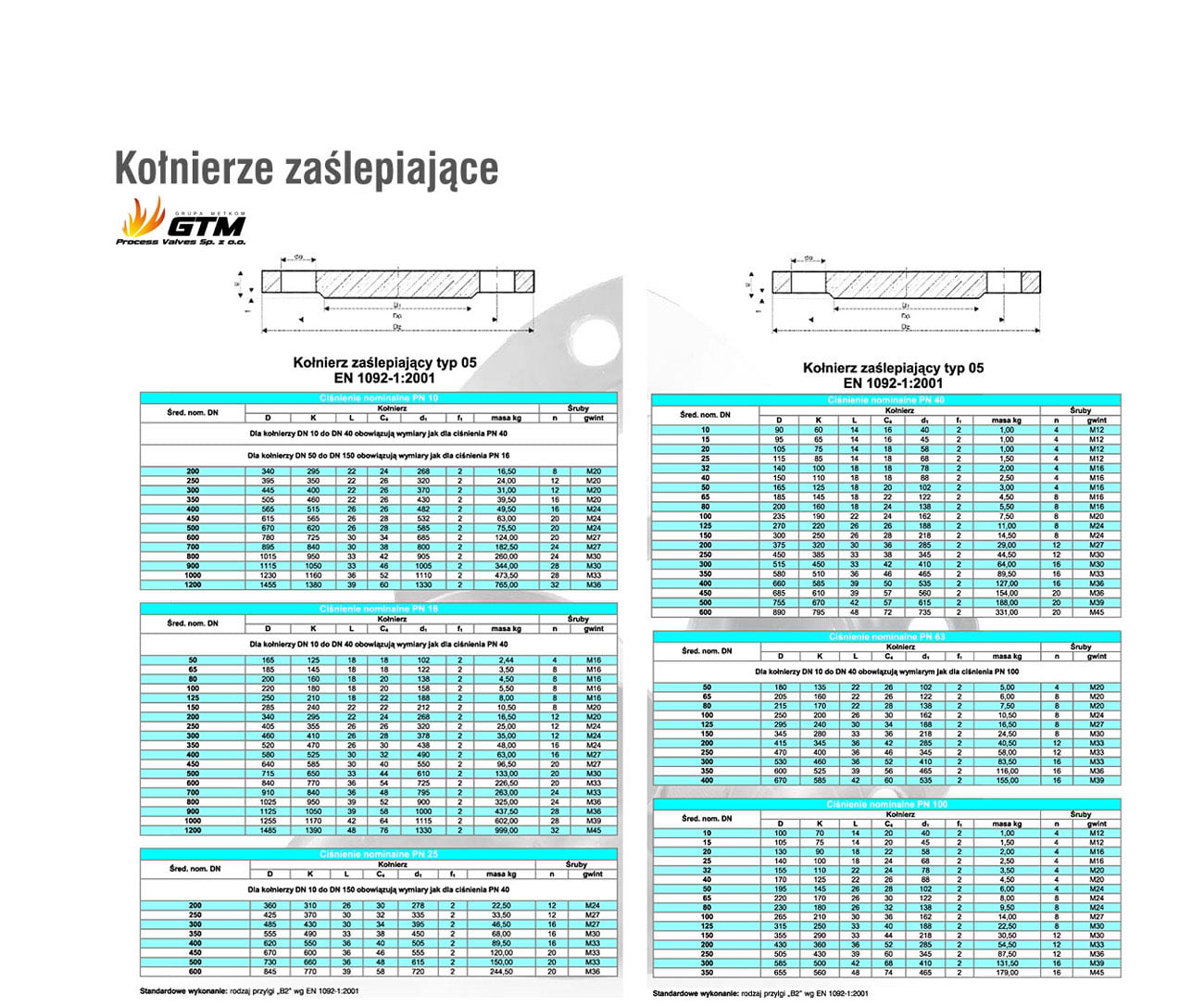

Steel flanges are available in various sizes: the diameter can range from DN10 to even DN2000. They are made of high-quality steel, which is characterized by a high degree of resistance to the working fluid. The use of this material also ensures protection against external conditions, enabling effective, tight, and durable connection of pipelines and pipes. Importantly, such a component also allows for the connection of systems to pressure vessels. Steel flanges are also used for mounting flanged fittings and joining bare pipe ends.

Flat steel flanges type 01 are one of the most popular models, characterized by high-quality craftsmanship and compliance with the EN 1092-1 standard. In addition to flat models, we can also distinguish steel flanges with necks, blind, threaded, or with a spigot – each of these products has a completely different purpose. The proposals from the GTM Process Valves offer will be perfect for creating solid, durable piping installations, ensuring the proper functioning of the entire system.

Steel Flanges – producer

Industrial components, such as steel flanges, should be manufactured from high-quality materials to ensure the durability of the entire installation. Within the GTM Process Valves assortment, you can count on a wide selection of steel flanges made according to European guidelines, which will perform excellently in various systems. We focus primarily on various types of steel that can be tailored to the requirements of a given solution. This material is characterized by a range of favorable parameters, such as resistance to the harmful effects of the working fluid and mechanical damage. As a result, it is widely used in industrial parts, where it provides necessary durability and optimal system parameters.

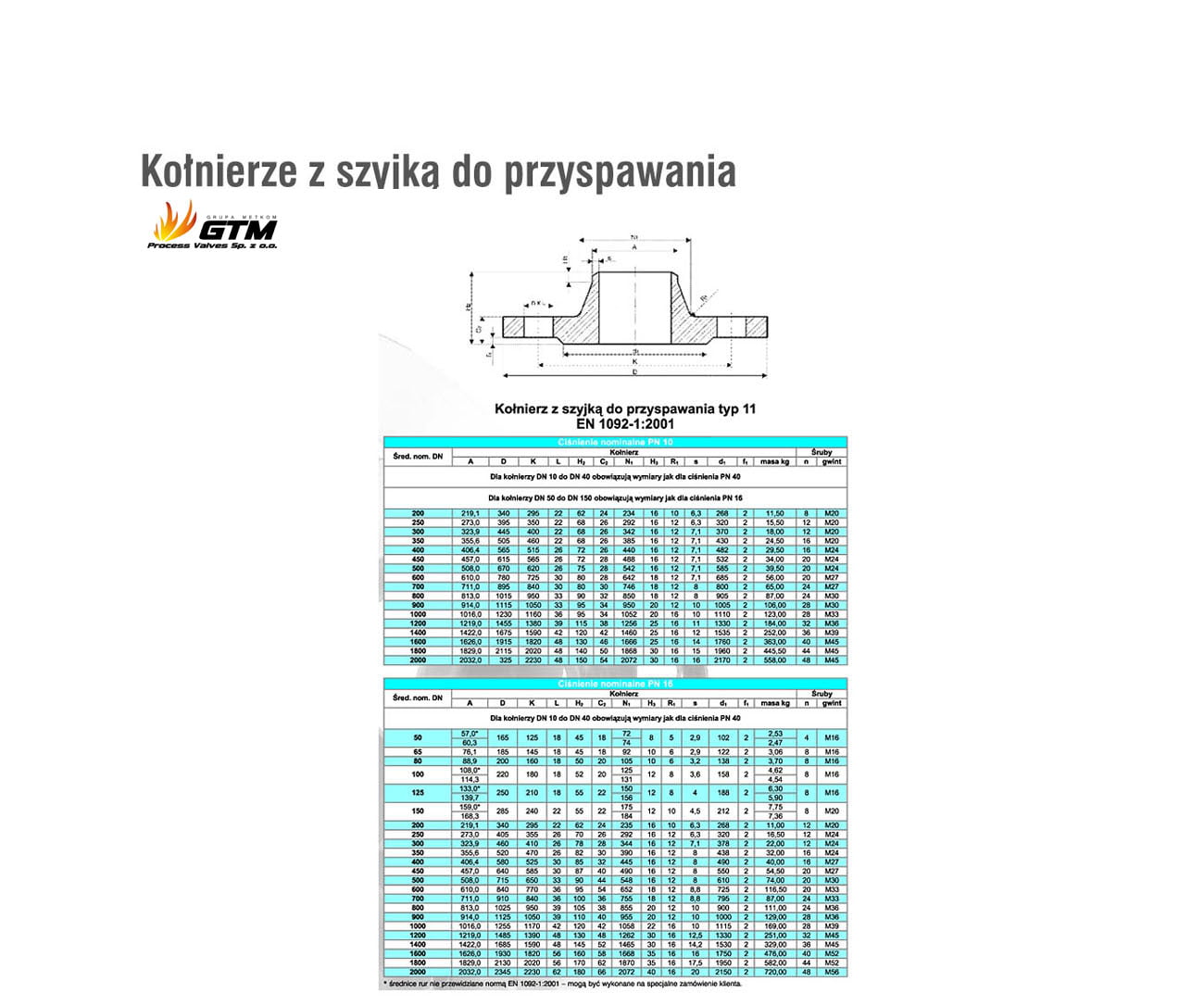

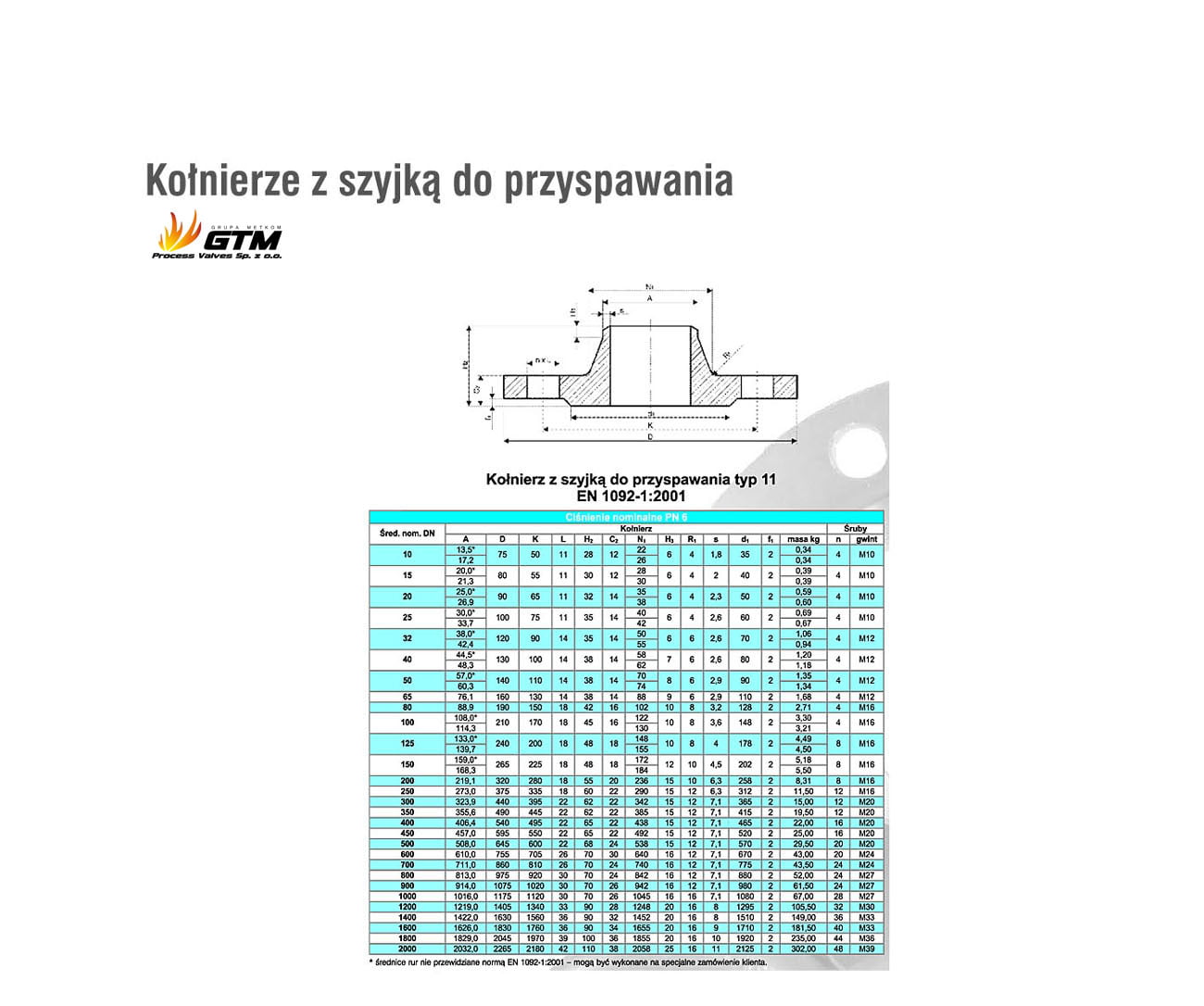

Weld-neck steel flanges

Steel flanges are classified based on their method of attachment. Some models can be connected to the installation using threads, while others are welded. Weld-neck steel flanges are specifically mounted by welding, ensuring high durability of the entire structure. Additionally, weld-neck steel flanges have a slightly different design compared to threaded models. A distinctive feature of their construction is a small neck, facilitating installation through welding. All flanges have special bores allowing for the dissipation of extreme temperatures and providing additional protection for the element. Such solutions are applied in both flat and threaded models. We invite you to explore the solutions from GTM Process Valves, which are used in many demanding systems.