Bellow Expansion Joints

Description: Elastomer expansion joint, Steel expansion joint

Diameters: DN 15 – DN 600, bigger sizes on request

Connections: Flange, thread, weld ends

Pressure: PN 10 – PN 16

Bellow: Elastomer: NBR, EPDM, Hypalon, Chloroprene, Steel: stainless steel, acid-resistant steel

Connection material: Flange or welding end made of carbon steel or stainless steel

Special equipment: Axial movement limiter, vacuum ring, PTFE lining

Usage: Processing industry, power plants, sewage treatment plants, waterworks, construction

Producers: Sferaco, Sobtrade, Zetkama, Burgmann, Ayvaz, Witzenmann, others

An expansion joint is a component of piping installations designed to compensate for movements that occur during the transportation of media such as gas or water. Bellows expansion joints are used to eliminate the thermal expansion of pipelines and in installations where vibrating equipment is connected. Expansion joints are made from various materials and selected based on the characteristics of the installation and the substance being transported. We distinguish between metal, fabric, and rubber models. Additionally, there is a classification based on function, where types of expansion joints include axial, lateral, angular, and Cardan joint.

Steel bellows expansion joint

A steel bellows expansion joint is installed in pumps, fuel injectors, or power generation installations. This construction allows for its installation in environments with high temperature and elevated pressure, such as pipelines transporting water, mines, and steelworks. It can also be used in chemical plants because it is resistant to the effects of strongly reactive substances. The bellows are most commonly made of galvanized sheet metal, which is corrosion-resistant and has increased durability.

A fabric bellows expansion joint

A fabric bellows expansion joint is used in exhaust and air installations. Its tasks include absorbing vibrations and compensating for axial, angular, and transverse displacements. It can withstand temperatures ranging from -90 degrees Celsius to +1000 degrees Celsius. To properly select it, certain factors should be considered, such as the concentration and density of the transported medium, the content of solid particles, temperatures, pressures, flow velocities, and the length of the conduit through which the substance is conveyed. Fabric models are made from durable materials such as polyester, aramid, nylon, glass, and silicone fibers.

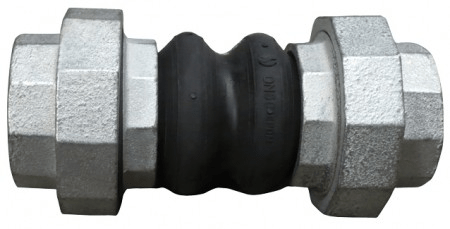

A rubber bellows expansion joint

Due to its wide range of applications, a rubber bellows expansion joint is installed practically everywhere, from sanitary installations to pipelines transporting drinking water, fuel, chemicals, acids, or food. Its temperature operating range is lower than that of fabric expansion joints, ranging from -40 degrees Celsius to +150 degrees Celsius. It is also additionally reinforced with special fibers made of polyester or nylon. It is important to ensure that installed expansion joints have all the necessary technical certificates allowing them to be used.