Sight glasses and sight ports – flow indicators

To maintain the proper functioning of chemical, energy, or heating installations, several key aspects need to be taken care of. One of them is monitoring the flow of the working fluid, which is facilitated by sight glasses/viewports. Thanks to such a solution, it is possible, among other things, to analyze the operating conditions of the circulation in pipelines or other types of installations. This is an extremely useful element in systems performing various tasks – when designing a system, it is certainly worth considering such components. We encourage you to familiarize yourself with the offer of GTM Process Valves. The sight glasses/viewports available in our assortment are made of the highest quality materials, ensuring high durability.

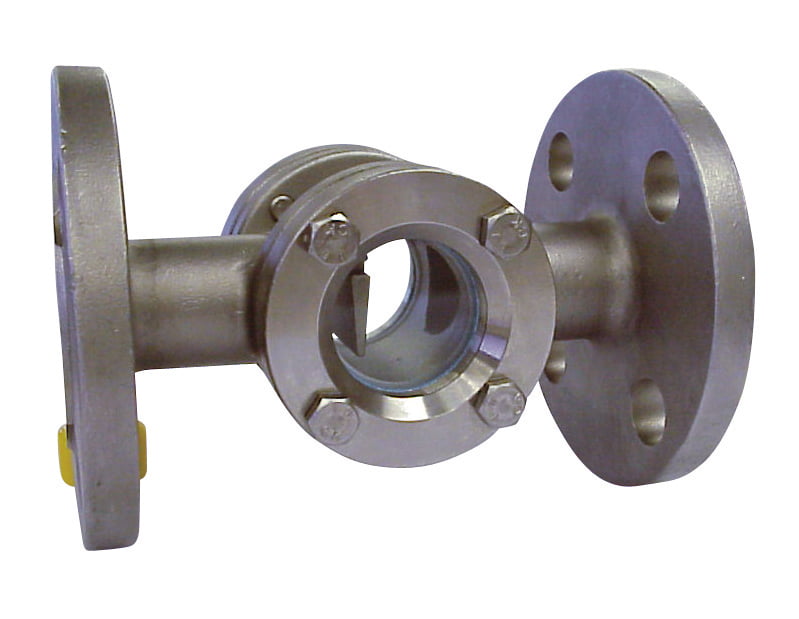

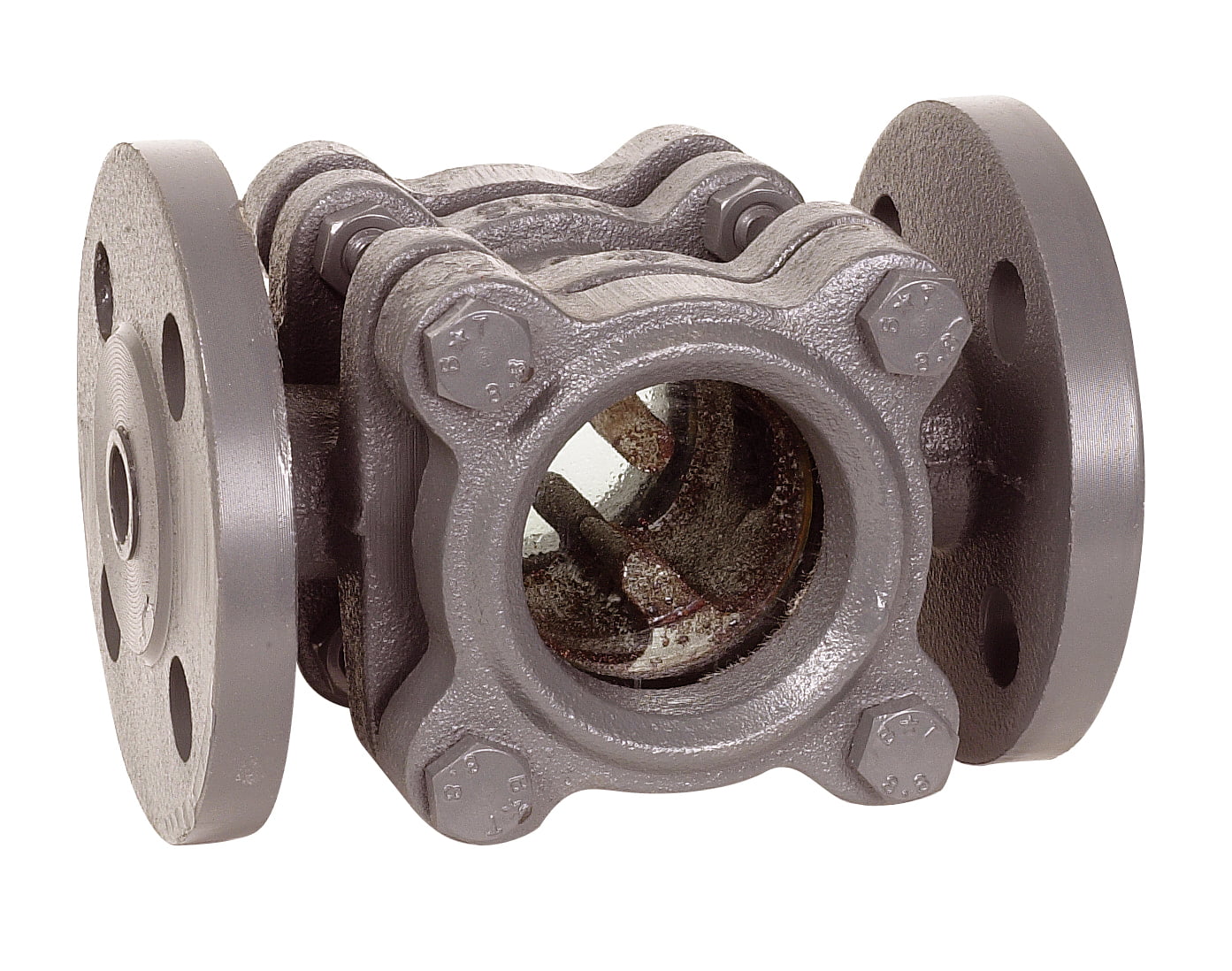

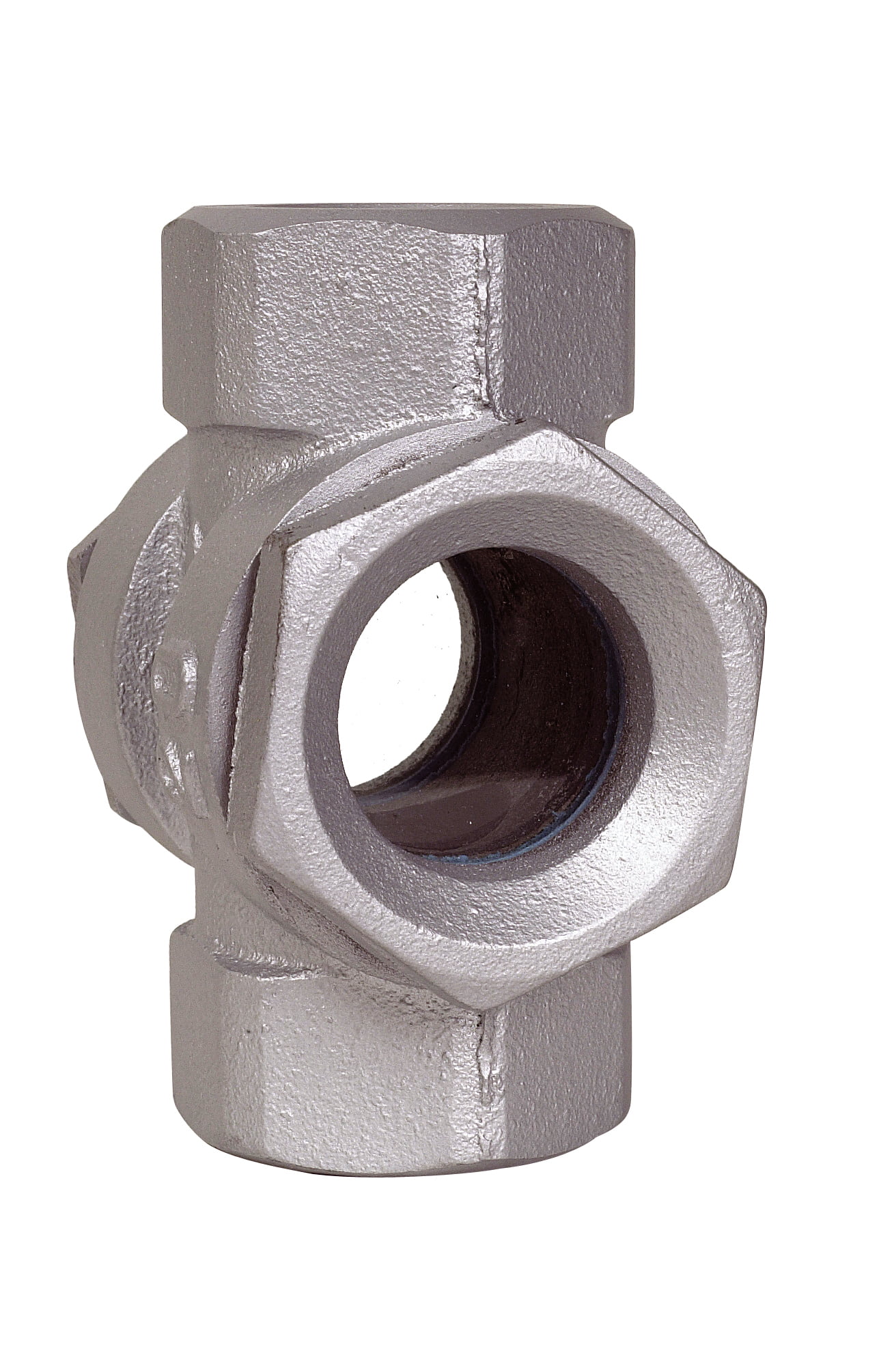

Description: Sight Glass

Diameters: DN 15 – DN 300

Connections: Flanged, Threaded, Welded

Pressure: PN 16 to PN 40

Body: Gray cast iron EN-GJL-250 (GG25), carbon steel 1.0619, stainless steel 1.4408, bronze, other materials (e.g., Duplex) upon request

Glass: Borosilikat, Natron-Kalk

Special executions: Flap, rotor, illumination, heating jacket, angled connector, three-way, double glass, wiper, dead space-free

Usage: chemical industry, power generation, district heating, etc

Producers: Chemitex, Andrex, Paracchini, Trumax

Sight glasses – flow indicators

Sight glasses are an extremely important component of any system through which liquid, gas, or steam flows. Their presence allows for the monitoring of circuit operation, enabling analysis of losses during flow. Importantly, they can be installed in both horizontal and vertical installations.

Appropriately selected products should primarily stand out for their high-quality construction. In the case of GTM Process Valves offerings, the components are manufactured from durable materials, translating into durability and resistance to harmful factors. The bodies of flow indicators have been made from EN-GJL-250 cast iron, carbon steel 1.0619, and stainless steel 1.4408. The sight glass, in turn, has been made from borosilicate or soda-lime glass, making it extremely durable and resistant to external conditions and the medium. GTM Process Valves also offers custom-made flow indicators upon customer request.

Sight Glass – construction

Sight glasses (flow indicators) are characterized by a construction composed of several elements that ensure the functionality of the whole. The sight glass consists of a connector, body, and glass, designed to provide the highest level of work safety. The use of high-quality materials ensures that sight glasses can handle aggressive fluids, gases, and even corrosion. The diverse construction of available models allows for the perfect fit for any installation. In the GTM Process Valves offering, solutions with diameters ranging from DN 15 to even DN 300 can be found.

The high durability of the component also includes acid-resistant properties and the ability to function correctly in extreme conditions. It is also worth mentioning the resistance to pressures ranging from PN 16 to PN 40. The construction can be installed in the installation using a flange, threaded connection, or simply welded.

Sight Glass – applications

Sight glasses are primarily used to observe flow in installations, allowing for the control of the working fluid circulation. As a result, it’s possible to analyze losses occurring due to flow. Importantly, sight glasses enable quick reactions to any situations that could disrupt the smooth operation of the system. Such elements should be installed in most installations where fluids, gases, or steam flow.