Strainers

Strainer filters constitute a key component in various installations. Due to their versatility, they find application in water networks, heating systems, and beyond – serving wherever efficient removal of impurities from the system is necessary. Well-crafted filters of the appropriate size enable effective collection of contaminants, allowing the passage of clean media to the subsequent parts of the system.

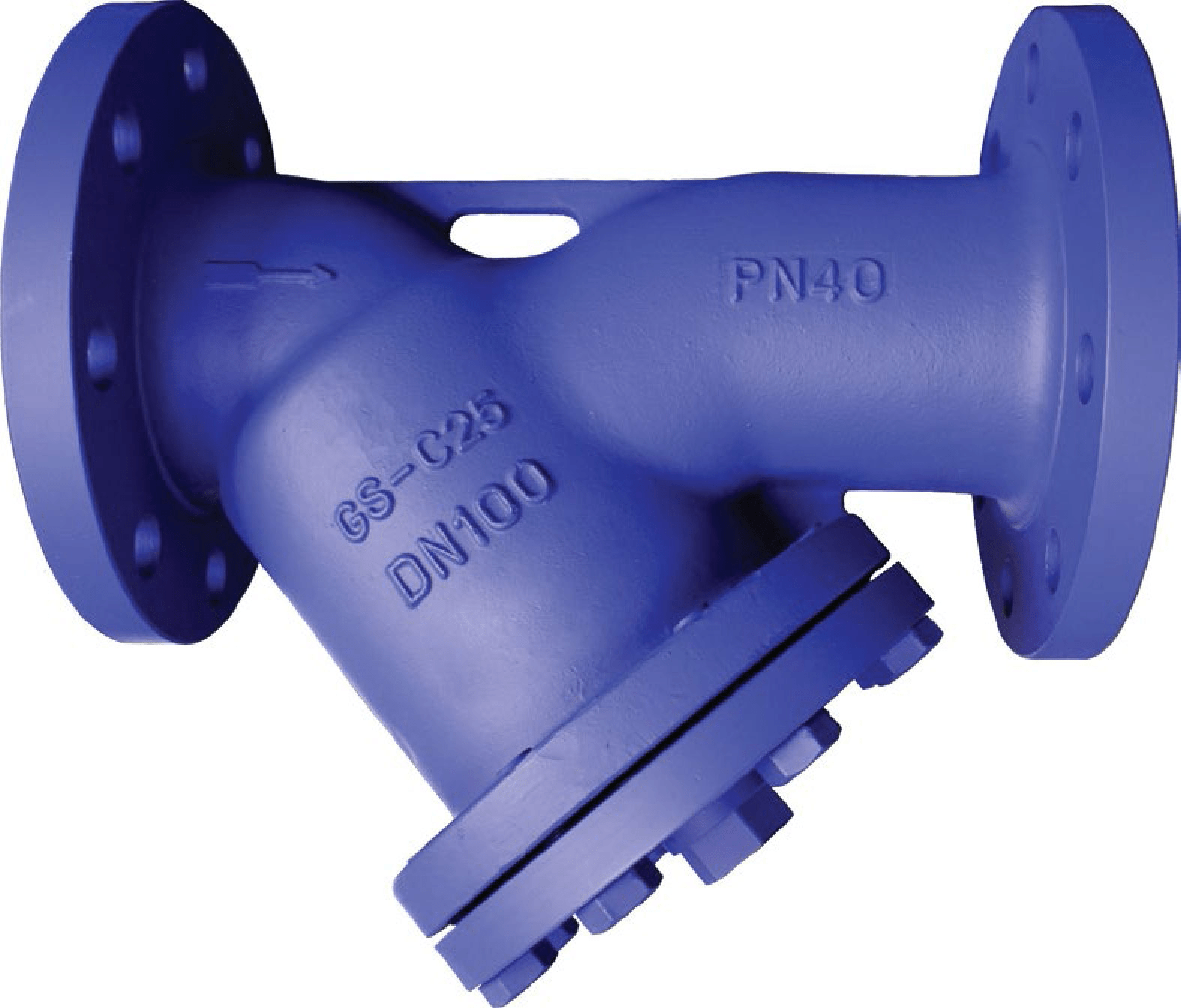

Strainer Filter

Strainers are used for purifying installations from substances that should not be present in the system. They are often used in pipelines to safeguard pumps, valves, regulators, measurement devices, and other components that could be prone to failure upon contact with inappropriate agents. One example of such a solution is the anti-sand strainer, which collects various fine solid particles that may have entered the installation, such as sand or gravel.

Another noteworthy type of this element is the flanged strainers, which are excellent for capturing fine substances and particles originating from pipe corrosion. As a result, they can contribute to the effective protection of the installation against damage and ensure its longer lifespan.

Types of Strainers

Depending on the needs of a particular installation, filters designed to separate substances with specific characteristics and sizes can be selected. For instance, mesh oil strainers are ideal fit for systems where liquid oil is in circulation. Constructed from a mesh or mat, they absorb unwanted substances, allowing the transmission of a clean agent and maintaining the efficient operation of various machinery and equipment.

In terms of precision, the strainer with a magnetic insert is noteworthy. Its function involves capturing ferromagnetic particles present in the medium to ensure the proper operational parameters of the system with very high precision. The magnetic strainer is primarily used in networks based on housing valves, as well as in various systems characterized by a high degree of technical sophistication.

Stainless Steel Strainer

In many situations, the key consideration is the strainer resistance to various factors – appropriately chosen materials ensure safe usage and long-term durability. The combination of stainless steel and carbon steel results in a stainless alloy that provides a high degree of corrosion resistance. Stainless steel strainer excel in installations that have constant contact with water. Thanks to such elements, there is no need to worry about product wear and damage that could occur due to material rusting during use.

Strainer for homes

The water strainer can be used not only in industrial machines and systems but also in single-family homes and apartment buildings. Installed in the drinking water and hot water supply systems, it allows for effective trapping and removal of impurities. Due to its working conditions, it must be resistant to rust, temperature changes, and contact with various liquids and gases that may occur in pipelines. A properly selected strainer ensures the safe use of the installation without concerns about leaks that could contribute to malfunctions.

The main areas of application for threaded strainers

Threaded strainers are primarily used in the energy industry. However, they can also be found in steam systems, central heating installations, as well as in evaporators and machinery used for gas delivery. Additionally, they are applied in refrigeration, oil, heating, and district heating systems. Filters of this type are designed to efficiently control the amount of debris accumulating on the meshes and, if necessary, clean the entire filter from undesirable substances.

Strainers – dimensions and sizes

Our offered products are characterized by high-quality craftsmanship – in our assortment, you can find conical strainers produced from stainless steel. They are designed for installations with varying pressure levels (from PN10 to PN40; ANSI 150–600 lbs). GTM Process Valves store provides products with a wide range of sizes, making them suitable for various systems. We offer solutions such as a 3/4-inch (DN 20) strainer, a 2-inch (DN 50) strainer, a 1/2-inch (DN 15) strainer, and many more.