High-performance butterfly valves

High-performance butterfly valves are suitable for use in various industries’ production processes. Their properties are most appreciated in production lines of companies specializing in chemistry, petrochemistry, and district heating. They prove to be effective wherever there are high temperatures or high-pressure fluids involved. We encourage you to explore the range of products offered by GTM Process Valves, which also includes advanced high-performance butterfly valves.

Description: high-parameter butterfly valves with double or triple eccentrically mounted discs

Connections: wafer and LUG type between flanges, flanged

Diameters: DN 50 – DN 1200; 2″ – 48″

Pressre: PN 10 – PN 40; ANSI class 150 – 300

Body: carbon cast steel GP240GH, stainless steel 1.4408

Disc: carbon cast steel GP240GH, stainless steel 1.4408

Seal: PTFE, metal / metal

Certification: marking CE, ATEX, Fire-Safe, TA-Luft

Usage: chemistry, petrochemistry, heating

Producers: Ebro Armaturen, Bray, Ghibson, Broen, Value Valves

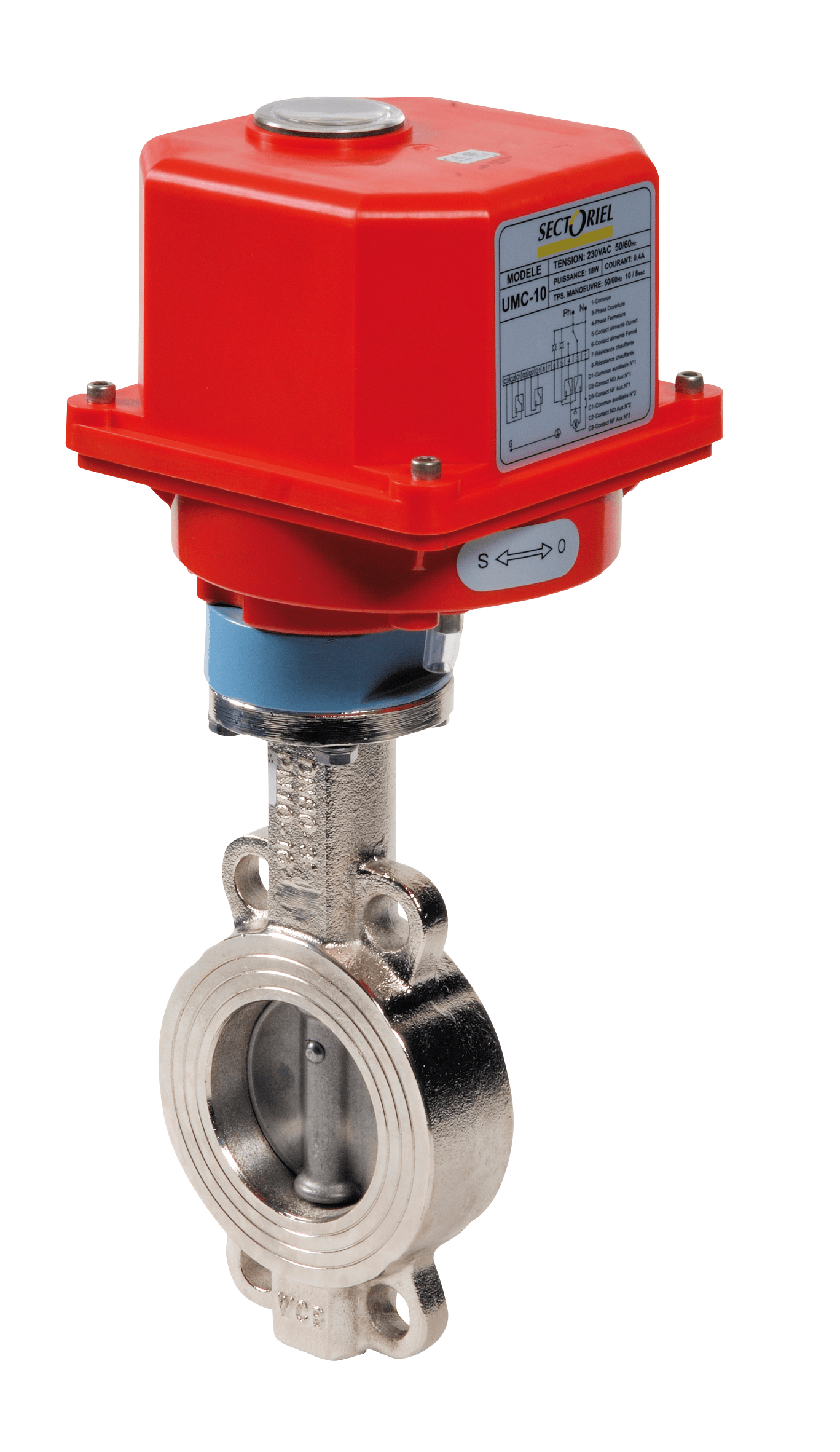

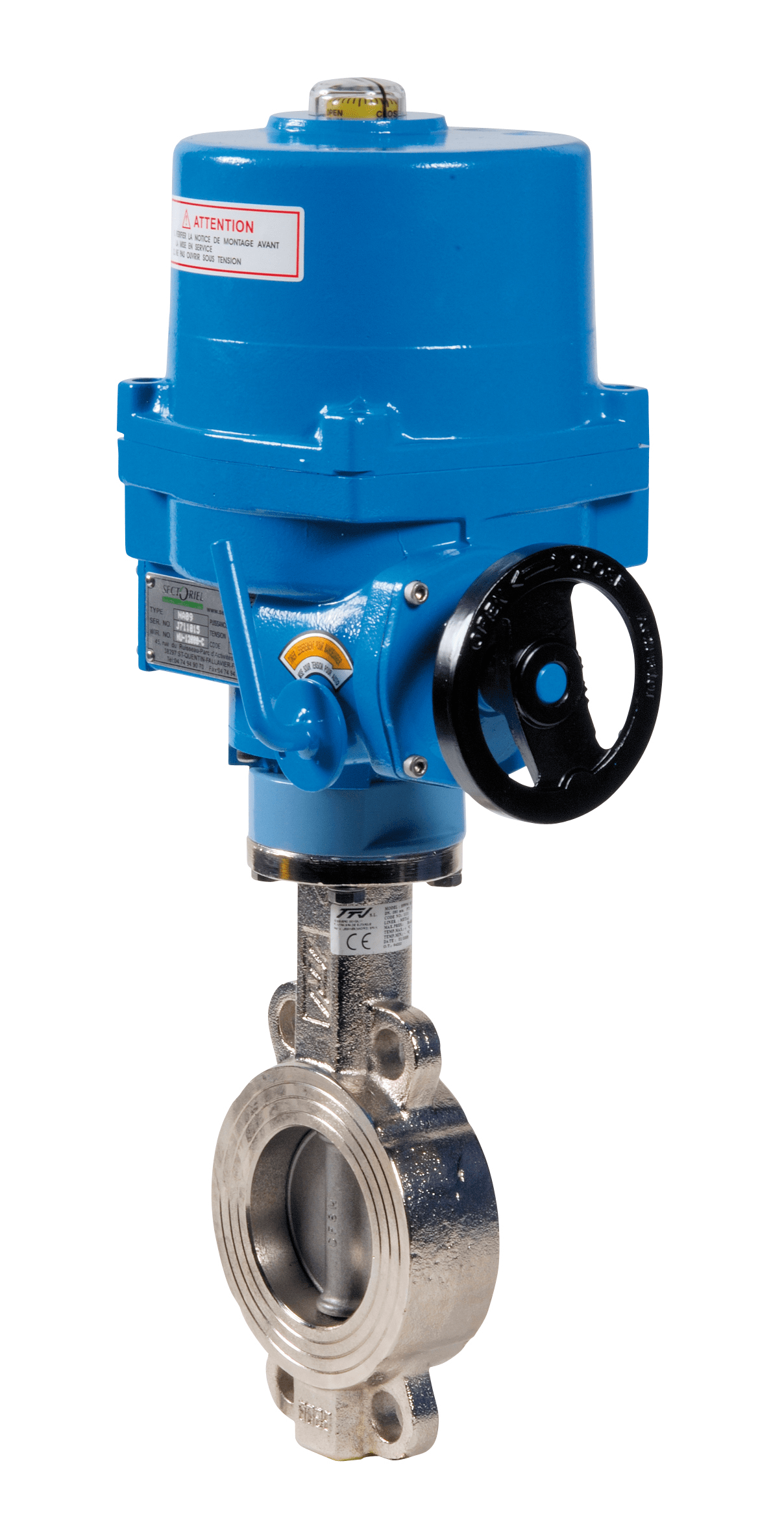

High-Performance Butterfly Valve

Why consider opting for a high-performance butterfly valve? Among their key advantages is their versatility – such a tool can be utilized in numerous production processes within the energy, chemical, petrochemical, or district heating industries. The high-performance butterfly valve also boasts significant resistance to high temperatures.

The materials used to create valves in this category set them apart with the highest standards of quality. Available in the GTM Process Valves offer, these high-performance butterfly valves are manufactured using GP240GH carbon steel, which provides protection against high temperatures, as well as 1.4408 stainless steel characterized by resistance to high temperatures and chemically aggressive substances. Purchasing such valves from GTM Process Valves ensures high, proven quality. All models in our range have CE markings; some have ATEX approval, Fire-Safe, and TA-Luft certifications, attesting to their standard of manufacture.

Double Eccentric Butterfly Valves

Double eccentric butterfly valves also find wide application in production lines for the chemical, petrochemical, or district heating industries. They perfectly complement any system of this kind – allowing for effective regulation of the working fluid flow. They can be used in systems involving contact with clean water, drinking water, chemical liquids, aggressive substances, and even hot fluids (up to 400°C). Double eccentric butterfly valves differ in the type of sealing used, commonly employing PTFE or Inconel. They may also come in a Fire-Safe design. These valves mainly vary in connector diameter, type, and PN pressure. At GTM Process Valves, we offer products ranging from DN 50 to DN 1000. Double eccentric butterfly valves come in wafer, LUG, and flanged body designs.

Triple Eccentric Butterfly Valves

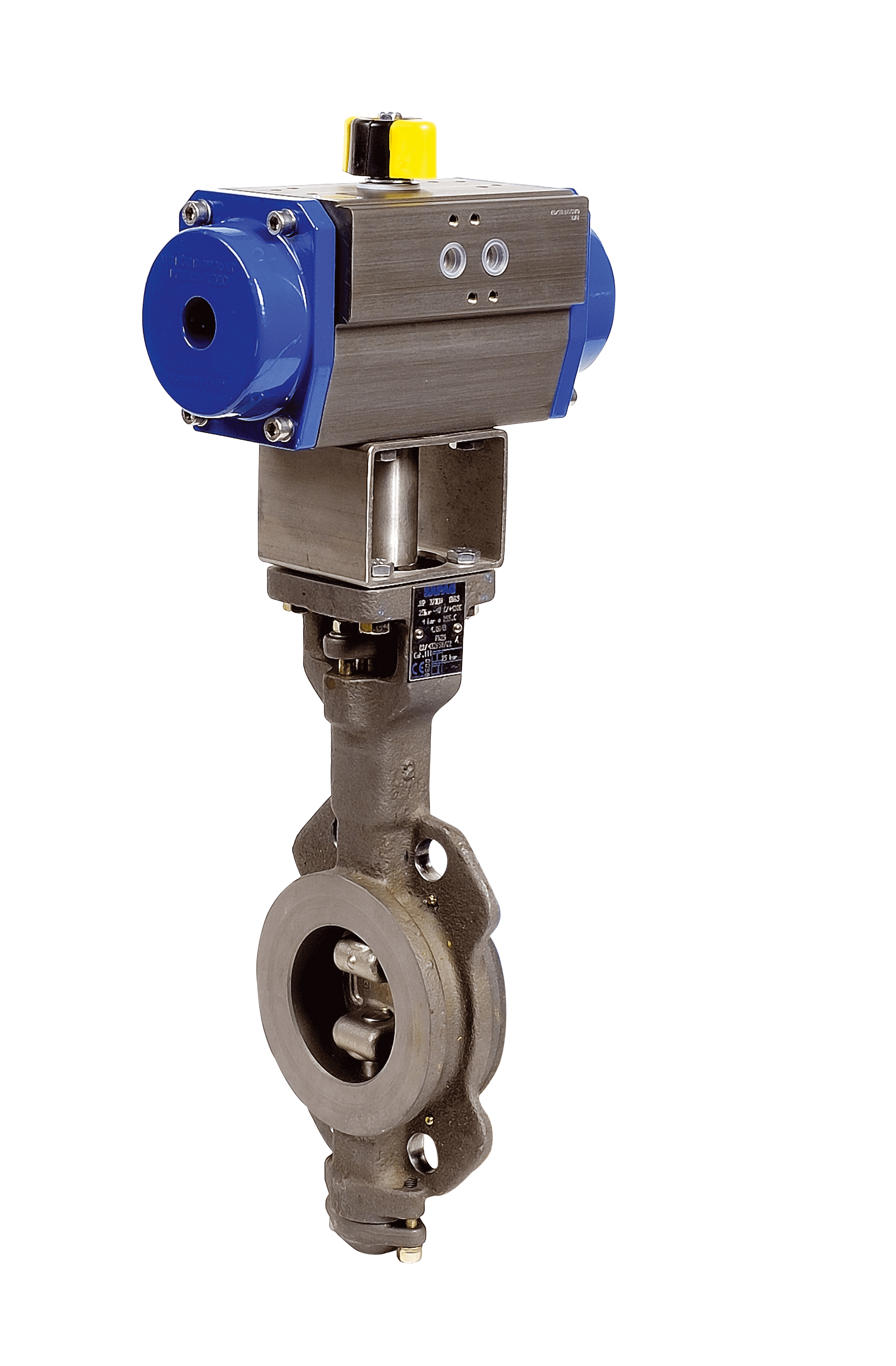

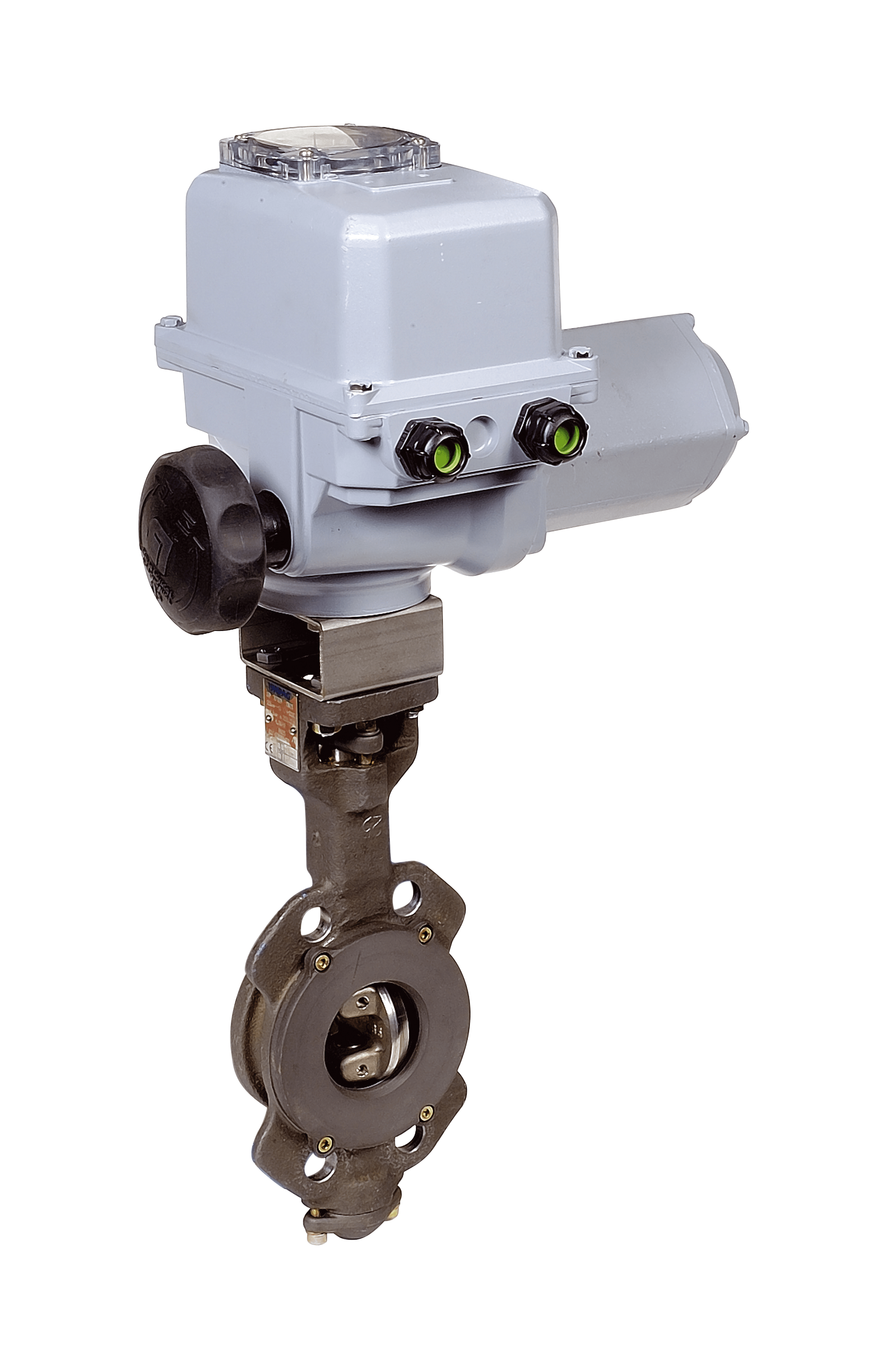

The properties offered by triple eccentric butterfly valves make them primarily suitable for district heating and power generation. Due to the use of carbon steel, they are resistant to high temperatures. Their key distinction lies in their resistance to extreme temperatures, ranging from as low as −39°C to 560°C.

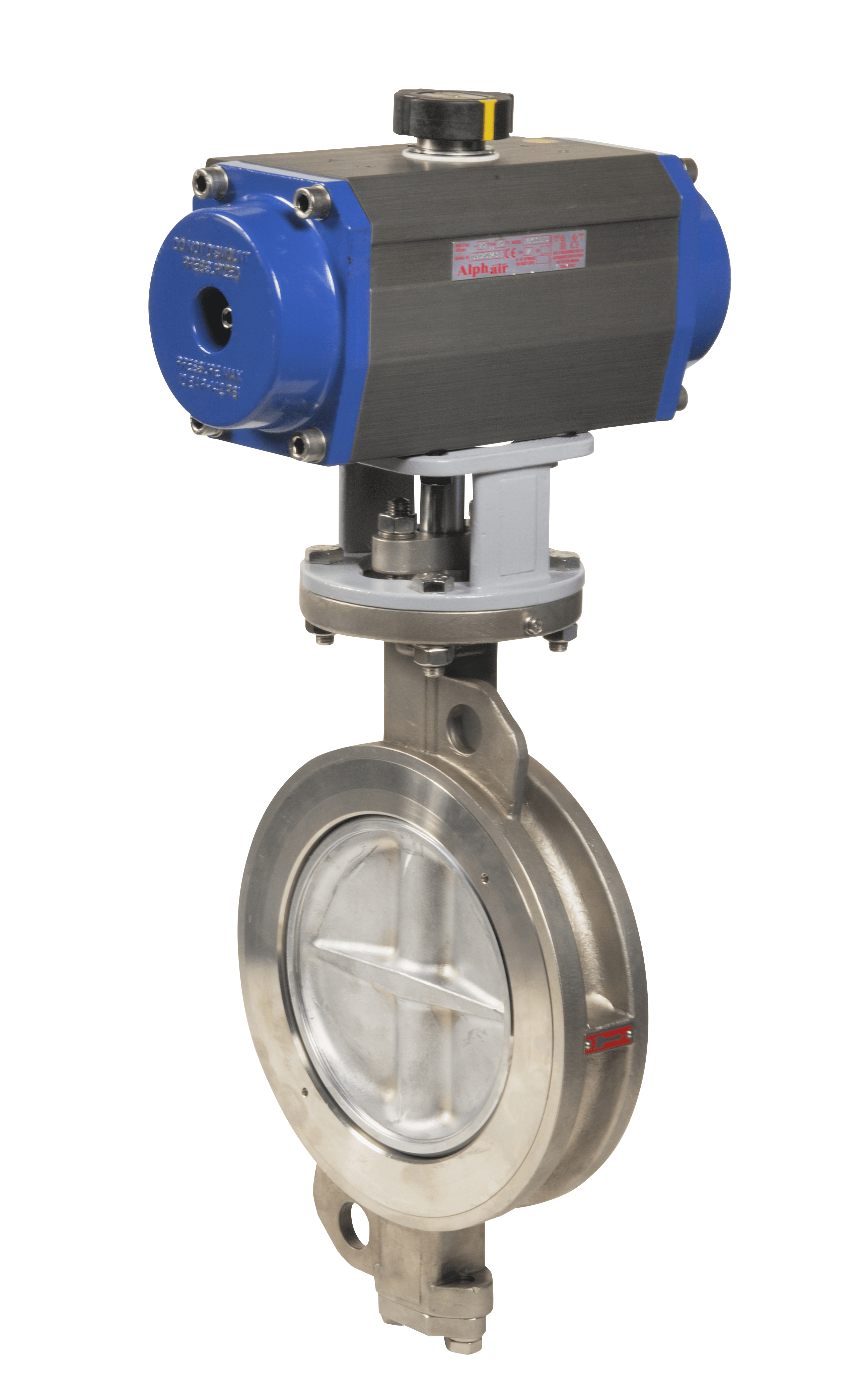

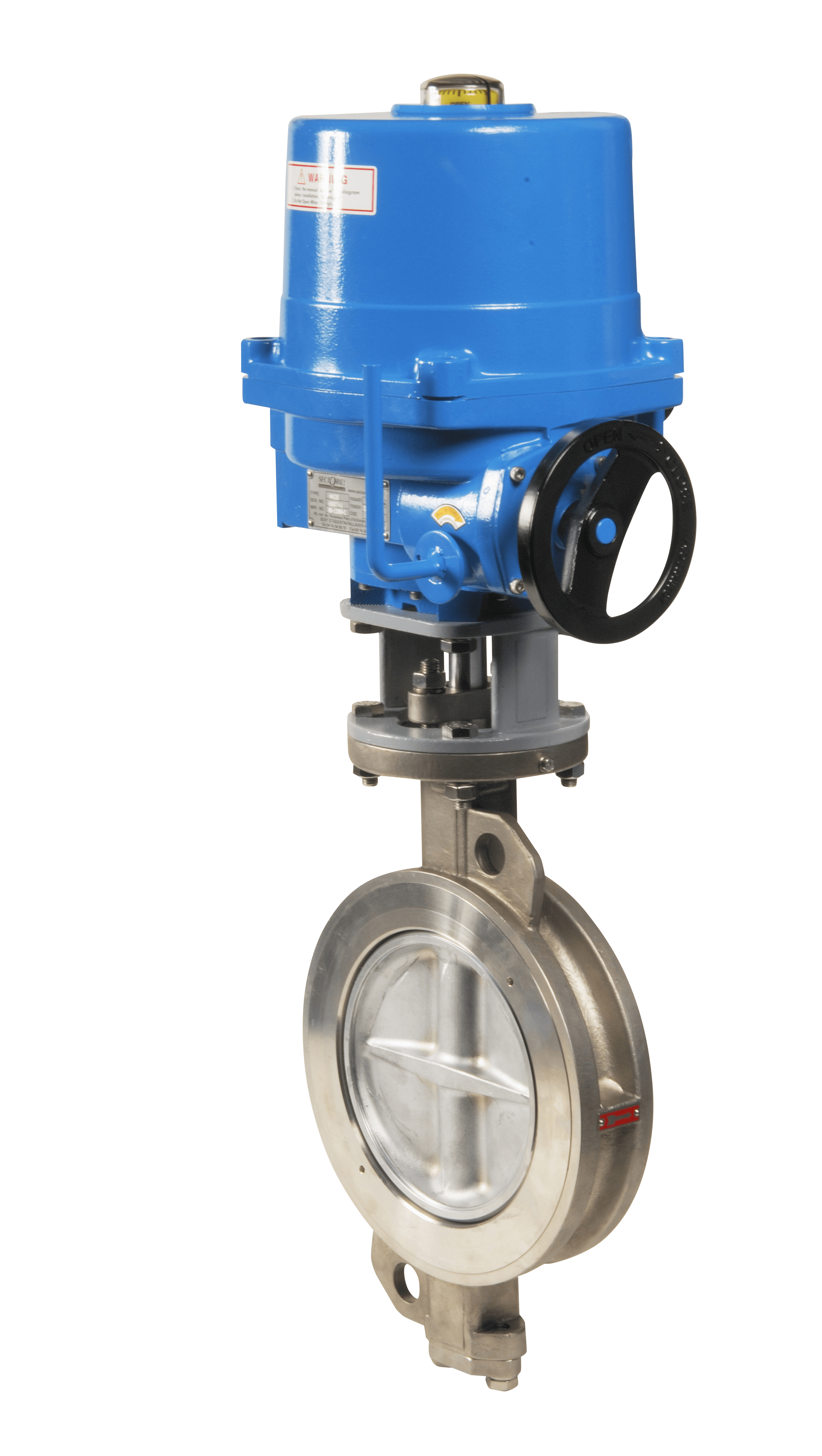

The drive mechanism is also a significant aspect – high-performance triple eccentric butterfly valves can be equipped with manual, electric, pneumatic, or hydraulic actuators. The operation principle of such valves is similar to other types of these solutions.